Technology for repairing roll by high-temperature molten-steel spray deposition based on thermit reaction

An aluminothermic reaction and spray deposition technology, which is applied in fusion spraying, metal material coating process, coating, etc., can solve the problems of complex surfacing repair technology, not too high hardness, and easy cracks, etc., to achieve deposition Controllable layer composition and thickness, excellent mechanical properties, and good metallurgical bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

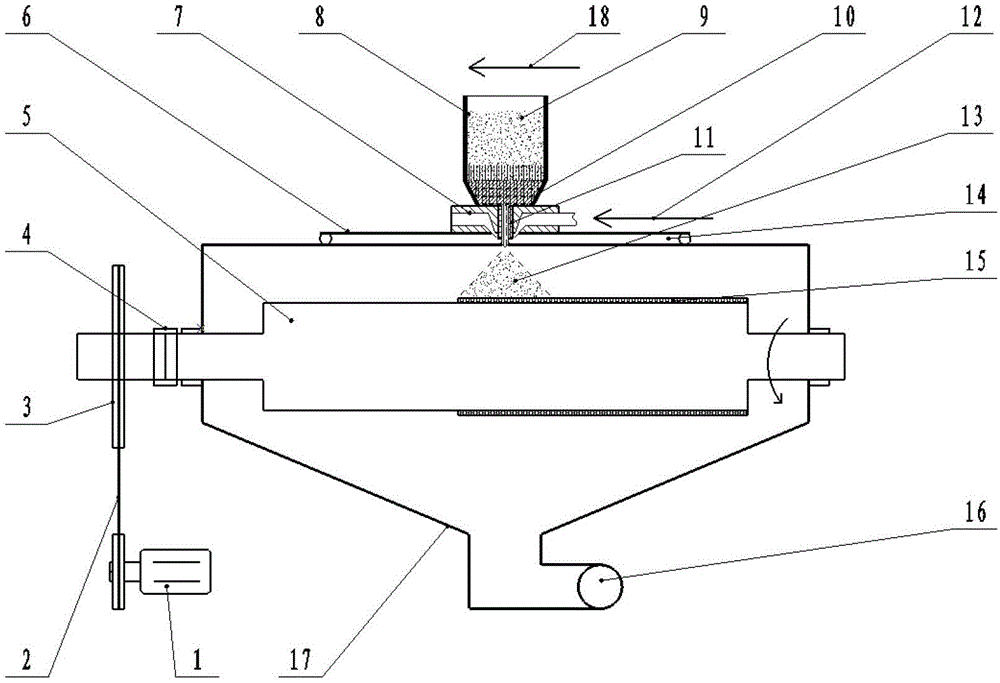

[0016] figure 1 Among them, the motor drives the gear plate 3 to rotate through the reducer 1 and the transmission chain 2, and the gear plate drives the roller 5 to rotate along the axis through the clamp 4. The thermite 9 mixed with alloying elements is placed in the crucible 8, the thermite is ignited by the burning magnesium strip and the thermite reaction occurs, and the high-temperature and high-alloy molten steel produced by the reaction passes through the ceramic filter layer 10 to filter out the thermite reaction The by-product oxide scum, the liquid flow leads to the atomizer spray gun 7 through the catheter 11, and finally meets the high-pressure nitrogen gas 12 passing through the atomization spray gun 7 at the atomization focus and is fully atomized to form an atomized liquid flow 13 at the same time , the atomized superalloy molte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com