Formaldehyde removing reagent for treating formaldehyde-containing fabric, and use method thereof

A formaldehyde and reagent technology, which is applied in the field of formaldehyde remover for fabrics containing formaldehyde, can solve the problems of low concentration of additives, difficulties, and unstable effects, etc., and achieve the effect of improving the composition and efficacy of reagents and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The formaldehyde-containing fabric is 50g of 53% viscose fiber and 47% cotton.

[0022] In the stirrer, add 2-azolidinone of 25g, the nano-titanium dioxide of 1g (average particle diameter 35nm, Shenzhen Jing material Chemical Co., Ltd.), 15g sodium dodecylbenzene sulfonate, 5g diatomaceous earth, 5g ethanol, 49g of distilled water was stirred at room temperature at a speed of 240 rpm for 3 minutes to prepare 100g of formaldehyde-removing reagent that was uniformly mixed.

[0023] The above-mentioned formaldehyde-removing reagent is added into water and mixed to form a treatment solution, and the above fabrics are soaked in the treatment solution, and the treatment solution submerges the fabric. After soaking at room temperature 25°C for 20 minutes, rinse the formaldehyde-removing agent on the clothes with clean water to remove formaldehyde.

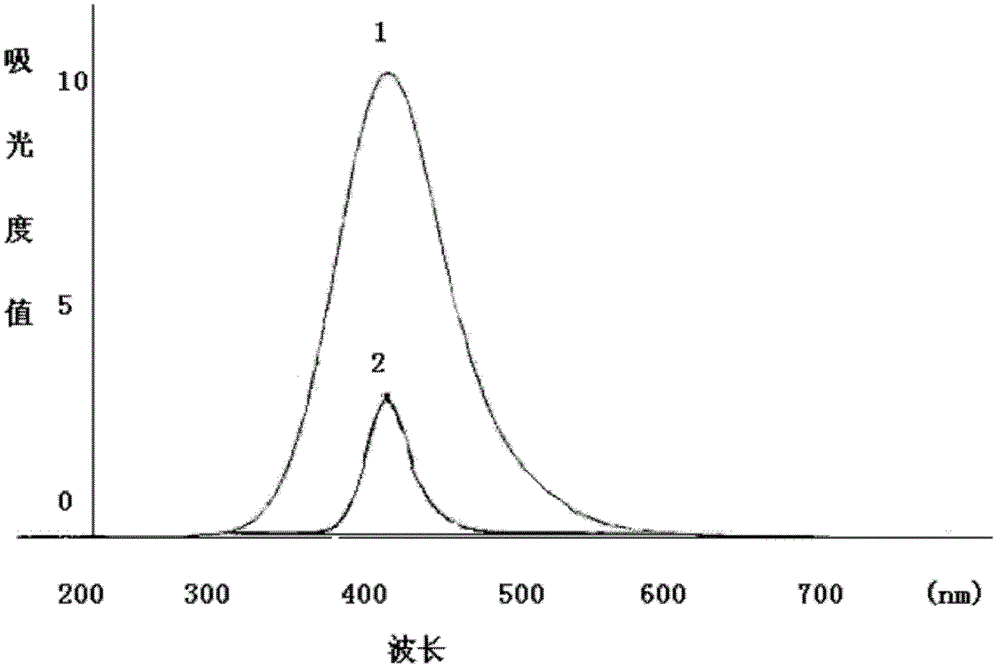

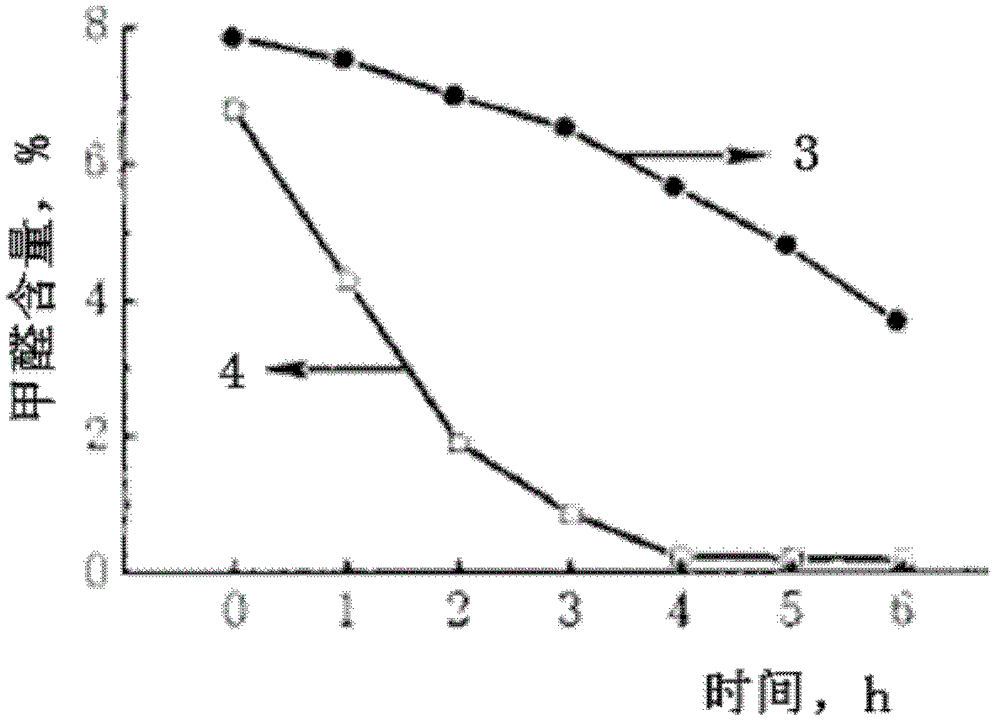

[0024] figure 1 It embodies the situation that the formaldehyde content of the fabric containing formaldehyde is detected befo...

Embodiment 2

[0030] The formaldehyde-containing fabric is 50g of clothes with 5% nylon, 60% cotton, and 35% cotton.

[0031]Add 34g sodium hypochlorite, 2g nano-zinc dioxide (average particle size 35nm, Shenzhen Jingcai Chemical Co., Ltd.), 16g sodium lauryl sulfate, 5g ethanol, 4g activated carbon (fruit shell / coconut shell type activated carbon, Nanjing Hansen Purification Engineering Co., Ltd.), 39g distilled water, stirred at room temperature with a rotating speed of 240 rpm for 3 minutes to prepare a uniformly mixed 100g formaldehyde removal reagent.

[0032] The above-mentioned formaldehyde-removing reagent is added into water and mixed to form a treatment solution, and the above fabrics are soaked in the treatment solution, and the treatment solution submerges the fabric. After soaking at room temperature 25°C for 20 minutes, rinse the formaldehyde-removing agent on the clothes with clean water to remove formaldehyde.

[0033] HPLC Same as Example 1, the formaldehyde content befo...

Embodiment 3

[0035] The formaldehyde-containing fabric is 50g of 63% polyester fiber, 33% viscose fiber, and 4% spandex.

[0036] Add 20g of 2,4-dinitrophenylhydrazine, 15g of sodium lauryl sulfate, 5g of ethanol, 10g of polyoxyethylene amide, and 5g of silicon carbide (brand: green silicon carbide micropowder for photovoltaic industry, Jiangsu Beisi Special silica powder Co., Ltd.), 2g iron powder (average particle size 200-500nm, Beijing Chemical Reagent Company, analytically pure), 43g distilled water, stir at room temperature with a rotating speed of 240 rpm for 3 minutes to prepare 100g of evenly mixed powder formaldehyde reagent.

[0037] The above-mentioned formaldehyde-removing reagent is added into water and mixed to form a treatment solution, and the above fabrics are soaked in the treatment solution, and the treatment solution submerges the fabric. After soaking at room temperature 25°C for 20 minutes, rinse the formaldehyde-removing agent on the clothes with clean water to rem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com