Construction method for large-volume concrete structure of bridge loading platform

A technology of large-volume concrete and concrete structures, which is applied in the direction of basic structure engineering and construction, and can solve problems such as bonding light resistance, aging, and corrosion, so as to improve integrity, maintain long-term durability, and avoid lax sealing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

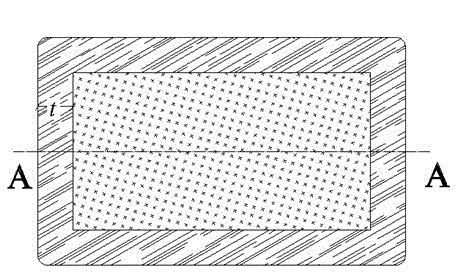

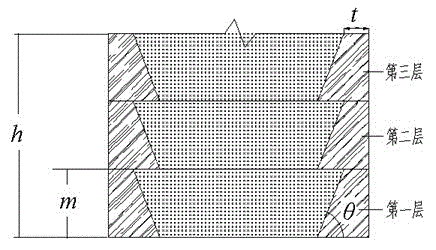

[0032] For a large-volume concrete structure of a bridge cap across the river and sea, its design thickness h is 5m, and the total concrete consumption is 4482.9m 3 , the bridge cap is constructed in two layers, and the thickness of the first layer is m 1 3m, the thickness of the second layer of pouring m 22m, the design thickness t of mass concrete at the edge is 0.8m, and the slope angle θ is 30°. The concrete construction process of this embodiment is:

[0033] 1) Erect the formwork, according to the inclination angle θ of the slope, the design thickness t of the mass concrete at the edge and the pouring thickness of the first layer m 1 , while pouring the first layer of side mass concrete and interior mass concrete;

[0034] 2) When the first layer of concrete reaches the form removal time, after the form removal, according to the inclination angle θ of the slope, the design thickness t of the bulk concrete at the edge and the pouring thickness of the second layer m 2 ...

Embodiment 2

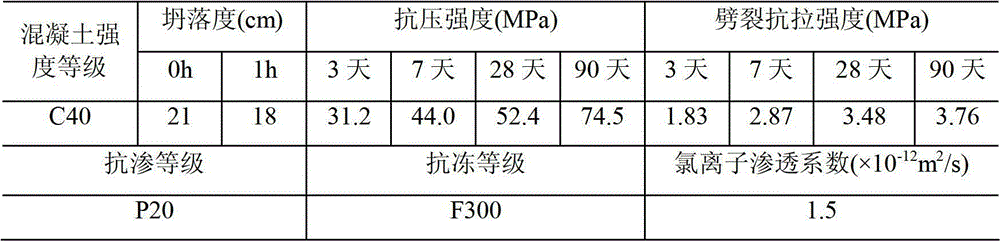

[0044] The bridge cap of a river-crossing bridge at the estuary is a large-volume concrete structure, which is a cylindrical structure with a bottom diameter of 40m and a height of 6m (that is, the design thickness h), and the total concrete consumption is 7500m 3 ; During the construction of the platform cap, it is poured in two layers, and the thickness of the first layer and the second layer is m 1 and m 2 Both are 3m, the design thickness t of mass concrete at the edge is 0.6m, and the slope angle θ is 45°. The specific construction process of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

[0045] The design strength grade of internal low-temperature rising and anti-cracking mass concrete used in this embodiment is C30, and the amount of each material in each cubic meter of internal concrete is: cement 105kg, fly ash 150kg, mineral powder 160kg, sand 795kg, stone 1055kg , water 142kg, superplasticizer 2.1kg, shrinkage reducing agent ...

Embodiment 3

[0053] The bridge cap of a river-crossing bridge is a large-volume concrete structure, which is a cuboid structure with a length of 28m, a width of 19m, and a height of 6m (that is, the design thickness h). The total concrete consumption is 3092m 3 ; During the construction of the platform cap, it is poured in two layers, and the thickness of the first layer and the second layer is m 1 and m 2 Both are 3m, the design thickness t of mass concrete at the edge is 0.5m, and the slope angle θ is 45°. The specific construction process of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

[0054] The design strength grade of internal low-temperature rising and anti-crack mass concrete used in this embodiment is C30, and the amount of each material in each cubic meter of internal mass concrete is: cement 150kg, fly ash 200kg, mineral powder 50kg, sand 750kg, Stone 1100kg, water 160kg, superplasticizer 4kg, shrinkage reducing agent 6kg. The same met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Splitting tensile strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com