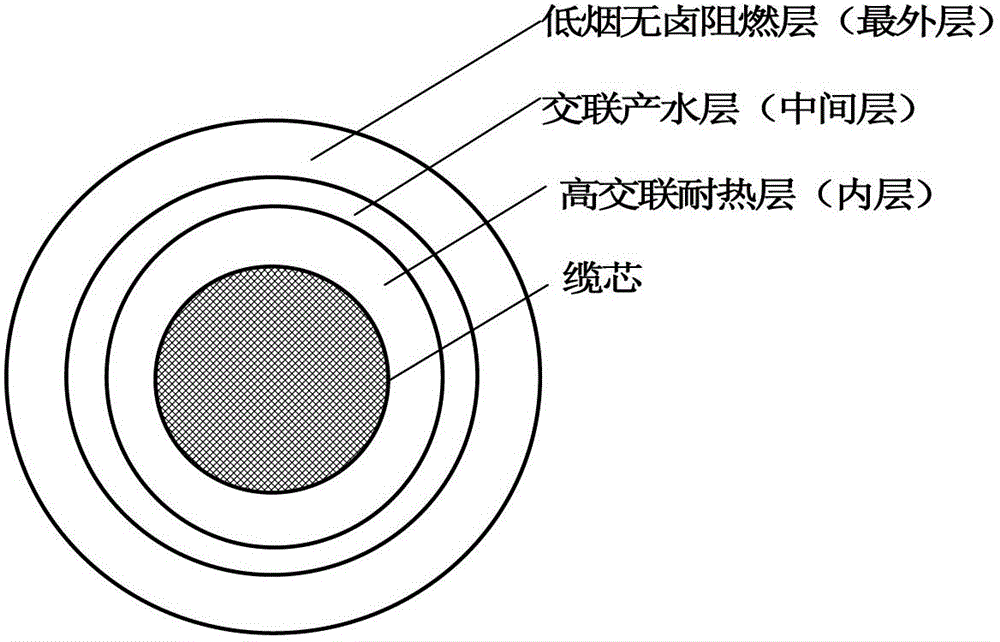

Low-smoke halogen-free flame-retardant cable and manufacturing method thereof

A technology of flame retardant cables and flame retardants, applied in the direction of insulated cables, conductor/cable insulation, cables, etc., can solve problems such as cable failure, cable safety hazards, insulation performance degradation of the insulation layer, etc., and achieve the goal of improving the withstand voltage level Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Preparation and performance of embodiment 1 cable insulation layer

[0051] Raw materials: The composition and weight ratio of the outer layer are: linear low density polyethylene: magnesium hydroxide: montmorillonite = 45: 50: 5;

[0052] The composition and weight ratio of the middle layer are: linear low density polyethylene: vinyltrimethoxysilane: dicumyl peroxide: dibutyltin dilaurate: stearic acid + zinc oxide = 95.4: 1: 0.1: 0.5︰3;

[0053] The composition and weight ratio of the inner layer are: linear low density polyethylene: vinyltrimethoxysilane: dicumyl peroxide: dibutyltin dilaurate: alkylsulfonic acid + tin oxide=95.3︰2︰0.2 ︰1︰1.5;

[0054] Among them, the grade of linear low density polyethylene is 218W.

[0055] Preparation method: Weigh various raw materials according to the above ratio. For the middle layer and the innermost layer, they are all processed in the form of A\B materials, that is, the polyolefin resin base material (in this embodiment,...

Embodiment 2

[0057] Preparation and performance of embodiment 2 cable insulation layer

[0058] Raw materials: The composition and weight ratio of the outer layer are: low-density polyethylene: polyphosphate amine: pentaerythritol: montmorillonite = 67: 20: 10: 3;

[0059] The composition and weight ratio of the middle layer are: low-density polyethylene: vinyltriethoxysilane: benzoyl peroxide: stannous octoate: magnesium hydroxide = 93.5: 1: 0.5: 1: 4;

[0060] The composition and weight ratio of the inner layer are: low-density polyethylene: vinyltriethoxysilane: benzoyl peroxide: organic titanium chelate: alkylsulfonic acid + tin oxide = 94.5: 2: 0.5: 2︰1;

[0061] Among them, the grade of low-density polyethylene is DJ210.

[0062] Preparation method: Same as in Example 1, by controlling the distribution ratio of each layer of the multi-layer co-extrusion device, the thickness of each layer of the obtained cable insulation layer is: the thickness of the outer layer is 0.3mm, the thic...

Embodiment 3

[0064] Preparation and performance of embodiment 3 cable insulation layer

[0065] Raw materials: The composition and weight ratio of the outer layer are: low-density polyethylene: aluminum hydroxide: montmorillonite = 47: 50: 3;

[0066] The composition and weight ratio of the middle layer are: low-density polyethylene: vinyltrimethoxysilane: 1,1-di-tert-butylperoxycyclohexane: tetraphenyltin: magnesium hydroxide = 94: 1: 0.5︰1︰3.5;

[0067] The composition and weight ratio of the inner layer are: low-density polyethylene: vinyltriethoxysilane: benzoyl peroxide: alkylbenzenesulfonic acid: benzenesulfonic acid + zinc oxide=94.5︰2︰0.2︰2 ︰1;

[0068] Among them, the grade of low-density polyethylene is QLT17.

[0069] Preparation method: Same as in Example 1, by controlling the distribution ratio of each layer of the multi-layer co-extrusion device, the thickness of each layer of the obtained cable insulation layer is: the thickness of the outer layer is 1.0mm, the thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com