Magnetic belt material with zero field cooling exchange bias effect and method for preparing magnetic belt material

A bias effect and magnetic band technology, applied in the field of magnetic materials and material physics, can solve the problems of high price and unfavorable industrial application of materials, and achieve the effect of low price and easy storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1 The preparation composition is Mn 50 CoNi 39 al 10 Magnetic Alloy Ribbon with Zero-Field Cooling Exchange Bias Effect

[0024] (1) Weighing ratio

[0025] According to chemical formula Mn 50 CoNi 39 al 10 Manganese (Mn) with a purity of 99.9%, cobalt (Co) with a purity of 99.9%, nickel (Ni) with a purity of 99.9% and aluminum (Al) with a purity of 99.9%.

[0026] (2) Melting ingot

[0027] Put the above weighed Mn, Co, Ni, Al blocks in the melting crucible, and pre-evacuate to 5×10 with a mechanical pump. -1 Pa; use a molecular pump to evacuate to 1×10 -4Pa, high-purity argon gas is introduced to make the internal pressure of the melting chamber reach 0.1MPa, an arc is generated, the melting current is 100A, the arc head is kept at 2-5cm above the sample and swings repeatedly in a small range for 1min, and each sample is turned over 3 times in total. Melt 4 times to make the composition of the prepared sample uniform; wait for the furnace cavity to co...

Embodiment 2

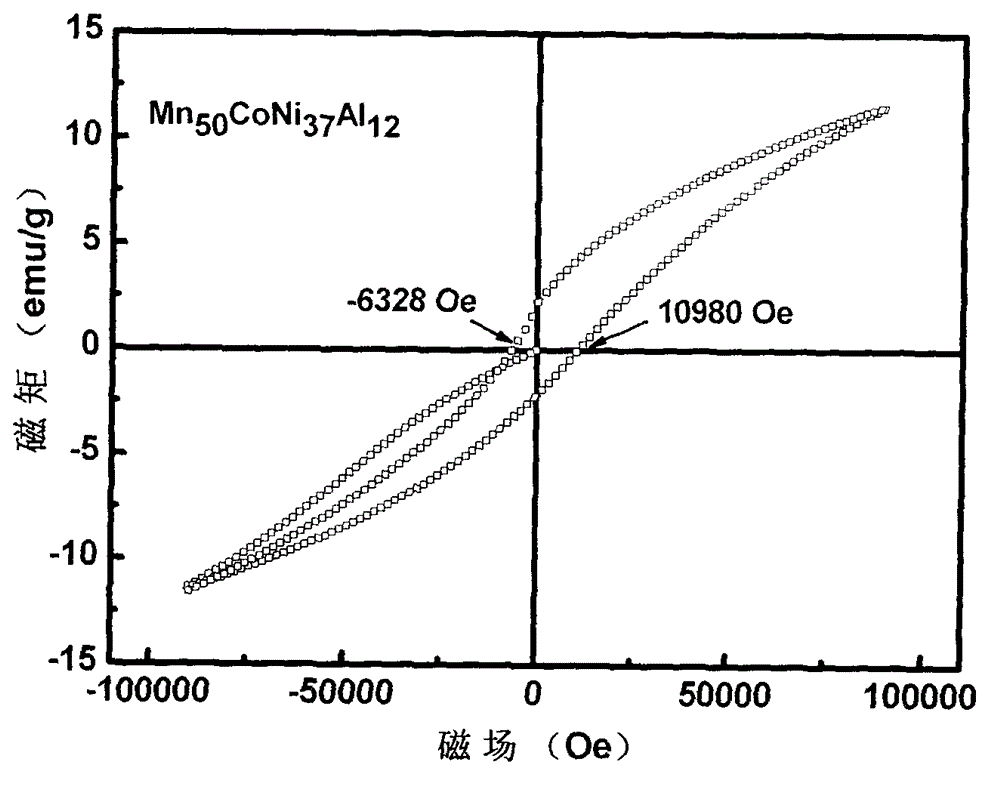

[0031] Example 2 The preparation composition is Mn 50 CoNi 37 al 12 Magnetic Alloy Ribbon with Zero-Field Cooling Exchange Bias Effect

[0032] (1) Weighing ratio

[0033] According to chemical formula Mn 50 CoNi 37 al 12 Manganese (Mn) with a purity of 99.9%, cobalt (Co) with a purity of 99.9%, nickel (Ni) with a purity of 99.9% and aluminum (Al) with a purity of 99.9%.

[0034] (2) Smelting nail material

[0035] Put the above weighed Mn, Co, Ni, Al blocks in the melting crucible, and pre-evacuate to 5×10 with a mechanical pump. -1 Pa; use a molecular pump to evacuate to 1×10 -4 Pa, high-purity argon gas is introduced to make the internal pressure of the melting chamber reach 0.1MPa, an arc is generated, the melting current is 100A, the arc head is kept at 2-5cm above the sample and swings repeatedly in a small range for 1min, and each sample is repeatedly turned over in this way for 3 times for melting 4 times to make the composition of the prepared sample uniform;...

Embodiment 3

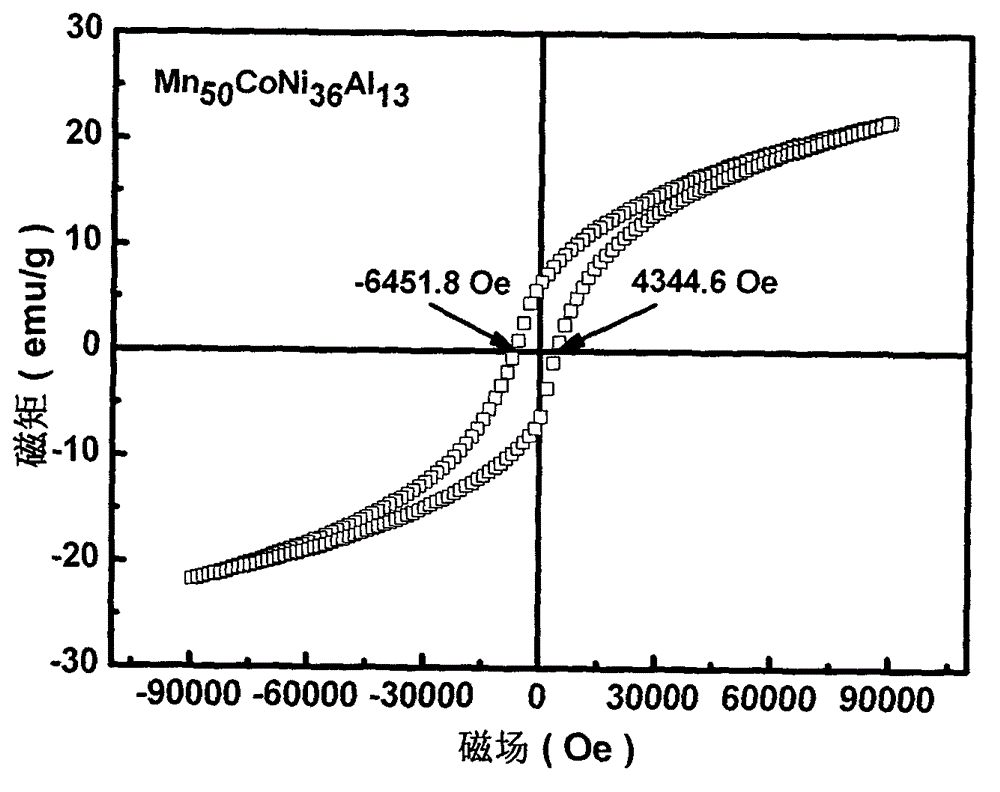

[0039] Example 3 The preparation composition is Mn 50 CoNi 36 al 13 Magnetic alloy strip with zero-field cooling exchange bias effect

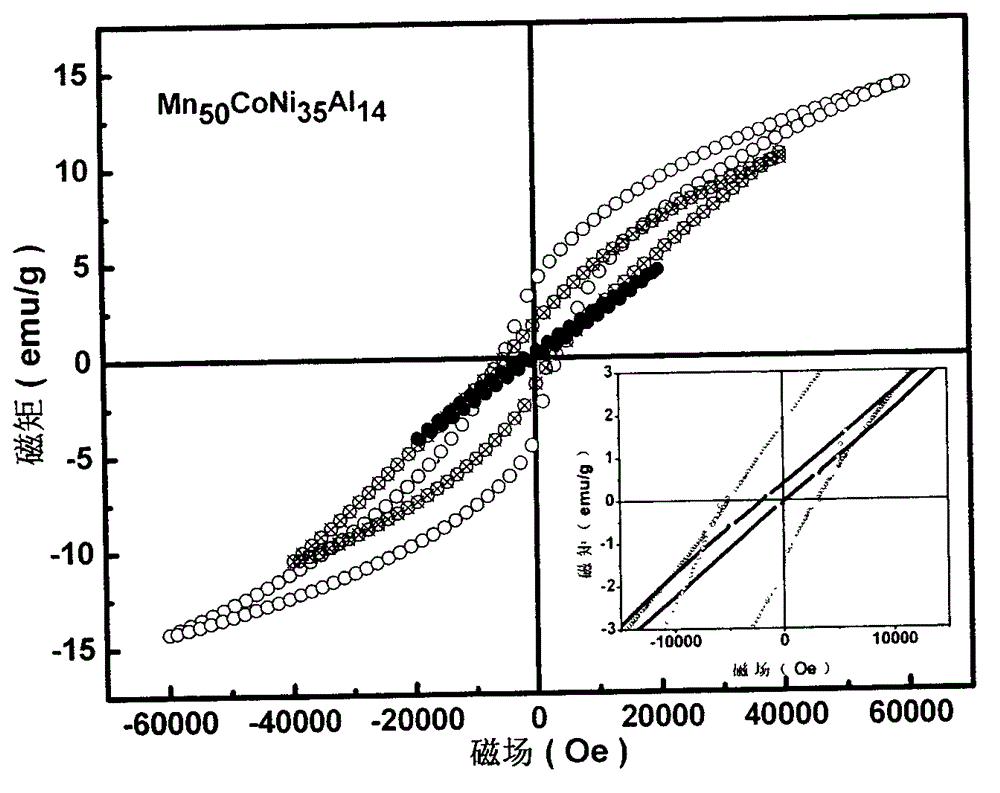

[0040] Its preparation method is the same as embodiment 2, and has measured the sample under zero-field cooling condition, the M-H curve figure of temperature T=4K and external magnetic field H=9T (such as figure 2 As shown), it is found that the hysteresis loop of the sample is shifted, which has an exchange bias effect, and the abscissas of the intersection points of the M-H closed curve and the coordinate axes are: H L =-6451.8Oe,H R =4344.6Oe, get the exchange bias field H E (H E =1053.6Oe) and coercive force H C (H C =5398.2Oe). Embodiment 4 preparation composition is Mn 50 CoNi 35 al 14 Magnetic coupling with zero-field cooling exchange bias effect

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com