High-power factor LED (light-emitting diode) driving circuit supporting silicon controlled rectifier dimming

A high power factor, LED driving technology, applied in the field of LED lighting, can solve the problems of low power factor and low circuit efficiency of low-power LED drivers, and achieve the effects of simple structure, improved reliability and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

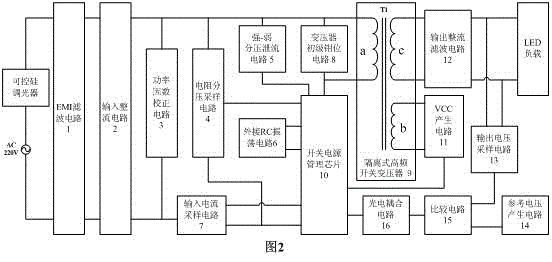

[0035] as attached figure 2 As shown, the high power factor LED drive circuit supporting silicon controlled rectifier dimming of the present invention includes an EMI filter circuit 1, an input rectifier circuit 2, a power factor correction circuit 3, a resistor divider sampling circuit 4, and a strong-weak divider discharge current Circuit 5, external RC oscillation circuit 6, input current sampling circuit 7, transformer primary clamp circuit 8, isolated high-frequency switching transformer 9, switching power supply management chip 10, VCC generation circuit 11, output rectification and filtering circuit 12, output voltage sampling Circuit 13, reference voltage generating circuit 14, comparator circuit 15 and photoelectric coupling circuit 16 are characterized in that:

[0036] The input end of the EMI filter circuit 1 is connected in series with a thyristor dimmer, connected to the AC mains, and the output end is connected to the input end of the input rectification circui...

Embodiment 2

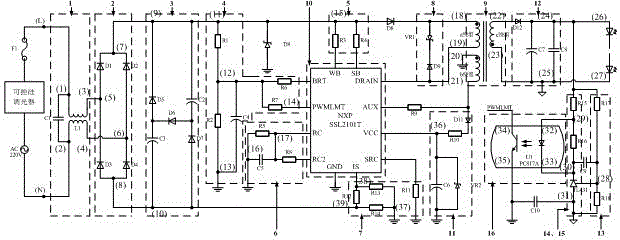

[0039] Embodiment two: as attached image 3 As shown, this embodiment is basically the same as Embodiment 1, and the special features are as follows:

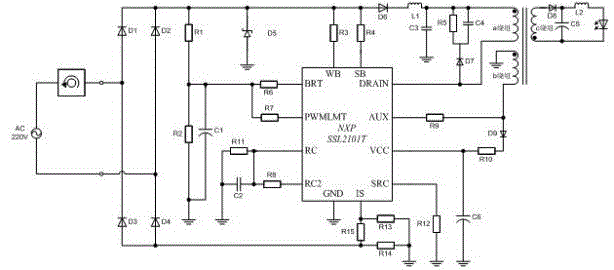

[0040] Described switching power supply management chip 10, uses the SSL2101T chip that NXP Company produces, and its pin is respectively WBLEED, SBLEED, VCC, GND, BRIGHTNESS, RC, RC2, PWMLIMIT, ISENSE, AUX, SOURCE, DRAIN, for convenience of description, Respectively abbreviated as WB, SB, VCC, GND, RC, RC2, PWMLMT, IS, AUX, SRC, DRAIN.

[0041] The EMI filter circuit 1 includes a capacitor C1 and a common-mode inductor L1. After connecting capacitor C1 in parallel at both ends (1) and (2) of the common-mode inductor L1, they are connected to the input terminals (L) and (N) of the LED drive circuit. terminal; the two ends of (3) and (4) of the common mode inductor are respectively connected to the input terminal (5) (6) of the input rectifier circuit 2.

[0042] The input rectifier circuit 2 includes a bridge rectifier compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com