Anaerobic digestion treatment method and system of kitchen waste

A technology for anaerobic digestion and kitchen waste, applied in the directions of biochemical equipment and methods, biochemical instruments, fermentation, etc., can solve the problems of adverse effects of methane conversion, affecting the utilization of kitchen waste, and death, and improve stability. effect on digestion efficiency, shortening anaerobic digestion cycle, and accelerating degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

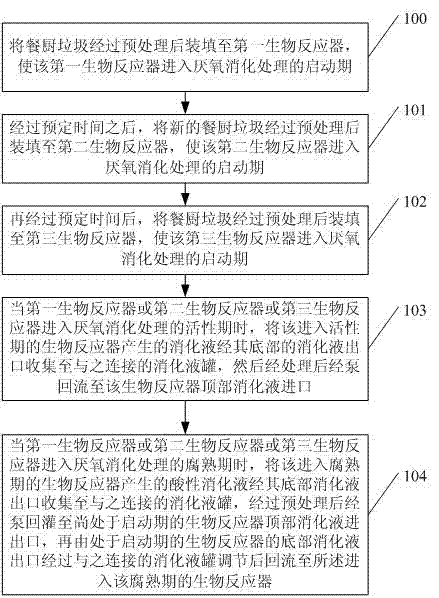

[0036] In order to solve the technical problems of long digestion period, low gas production and gas production inhibition caused by high salt, VFA and ammonia nitrogen accumulation in the anaerobic digestion process of kitchen waste, the present invention provides an anaerobic food waste anaerobic digester. Digestive processing systems and methods.

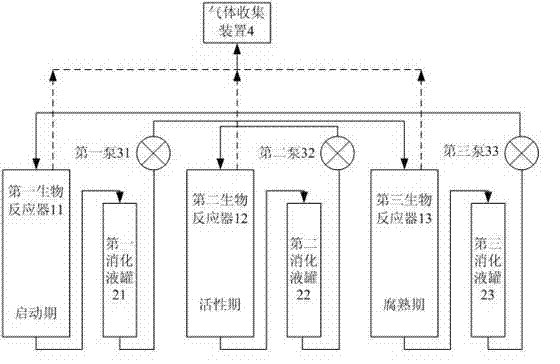

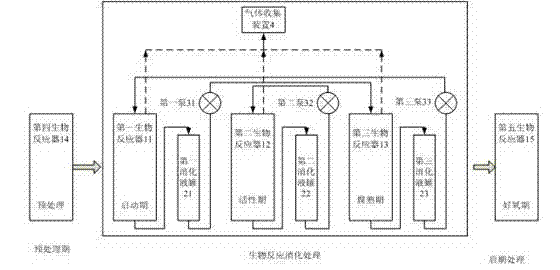

[0037] see figure 1 , is a structural schematic diagram of Embodiment 1 of an anaerobic digestion treatment system for food waste provided by the present invention.

[0038] The system provided in Embodiment 1 includes:

[0039]The first bioreactor 11 in the start-up phase, the second bioreactor 12 in the active phase, and the third bioreactor 13 in the decomposing phase for anaerobic digestion treatment; the first digestion liquid tank 21, the second digestion Liquid tank 22, third digestive liquid tank 23; first pump 31, second pump 32, third pump 33; multiple liquid connecting pipes connecting each bioreactor and digestive l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com