Production method and culturing device of high-vigor nitrifying bacteria products

A technology of nitrifying bacteria and production methods, applied in biochemical cleaning devices, biochemical equipment and methods, enzymology/microbiology devices, etc., can solve high production costs, unsuitable for large-scale production, and heavy workload of elution and collection and other issues to achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, embodiment the invention is further described.

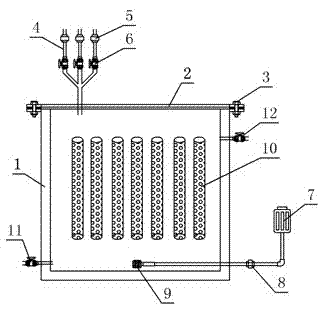

[0015] Such as figure 1 Shown is a culture device for cultivating high-activity nitrifying bacteria products, including a tank body 1 made of heat-insulating material, with a temperature control device in the tank body to create temperature conditions for cultivating nitrifying bacteria, and a cover 2 fixed on the tank body 1 through a flange 3 The upper part of the upper part of the lid 2 is provided with a four-way pipe 4, one of the pipes of the four-way pipe 4 is inserted into the tank body, and the nutrient solution is delivered to the inside of the tank body 1 through the other three pipes, and the three pipes are respectively used to transport three kinds of different components. The nutrient solution prevents the nutrient solution from reacting and precipitation before mixing, and the three pipelines are provided with a liquid filter 5 and a valve 6, and the liquid f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com