Bearing bush alloy layer working surface fluoride-free and lead-free double-layer alloy plating structure and plating technology

A technology of alloy coating and working surface, applied in the field of bearing bush processing, can solve the problems of poor performance and short service life of bearing bush coating, and achieve the effects of high corrosion resistance, extended service life and consistent color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

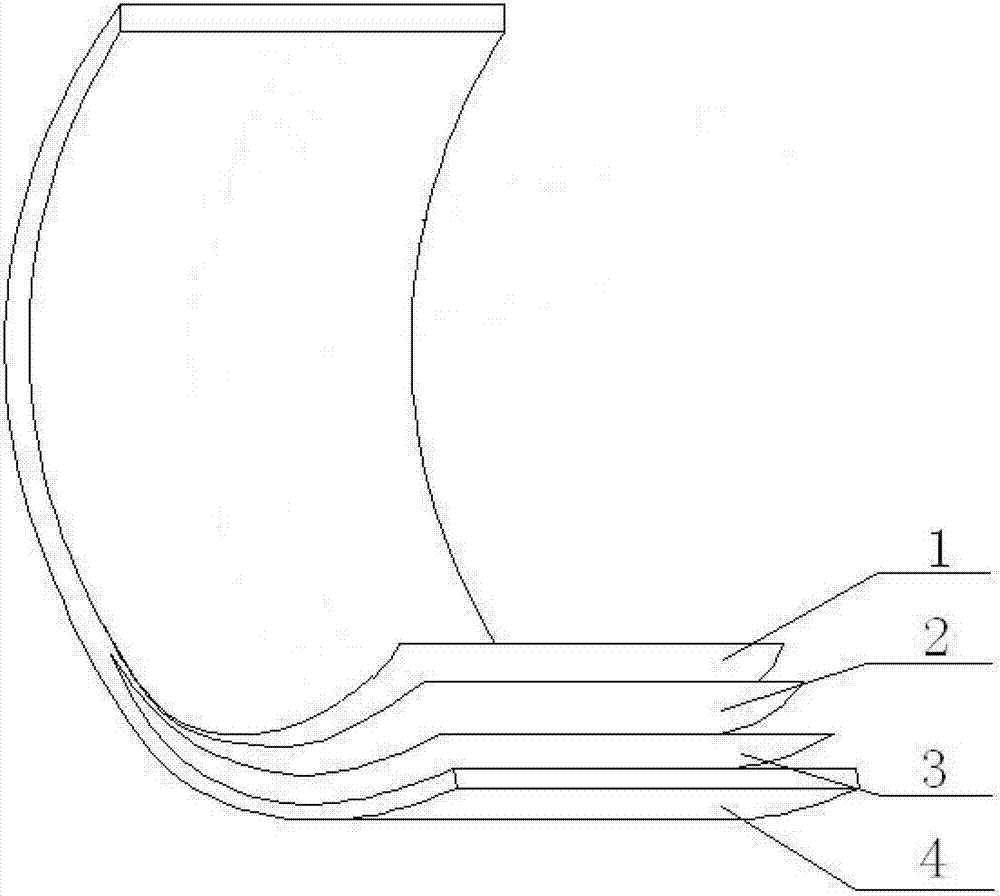

[0014] Bearing pad alloy layer The double-layer alloy coating structure of the working surface includes a bearing pad 4, and the inner surface of the bearing pad 4 is coated with double-layer tin-copper alloy coatings 3 and 2, and the inner layer of the tin-copper alloy coating layer 3 that is close to the inner circle of the bearing pad The copper content is higher than the copper content in the outer tin-copper alloy coating 2, the weight ratio of copper in the inner tin-copper alloy coating 3 close to the inner circle of the bearing bush is 10%, the weight ratio of tin is 90%, and the outer tin-copper alloy coating In 2, the weight ratio of copper is 3%, and the weight ratio of tin is 97%, and a pure white tin layer 1 is also plated on the alloy coating layer 2 of the outer layer system.

[0015] The double-layer alloy coating process on the working surface of the alloy layer of the bearing bush includes the following steps:

[0016] (1) Firstly, ultrasonic cleaning is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com