Processed high-purity copper material having uniform and fine crystalline structure, and process for production thereof

A technology of crystal structure and manufacturing method, applied in the field of high-purity copper processing materials, can solve problems such as difficulty in obtaining fine grains stably, and achieve the effect of reducing the occurrence of defects and uniform sputtering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

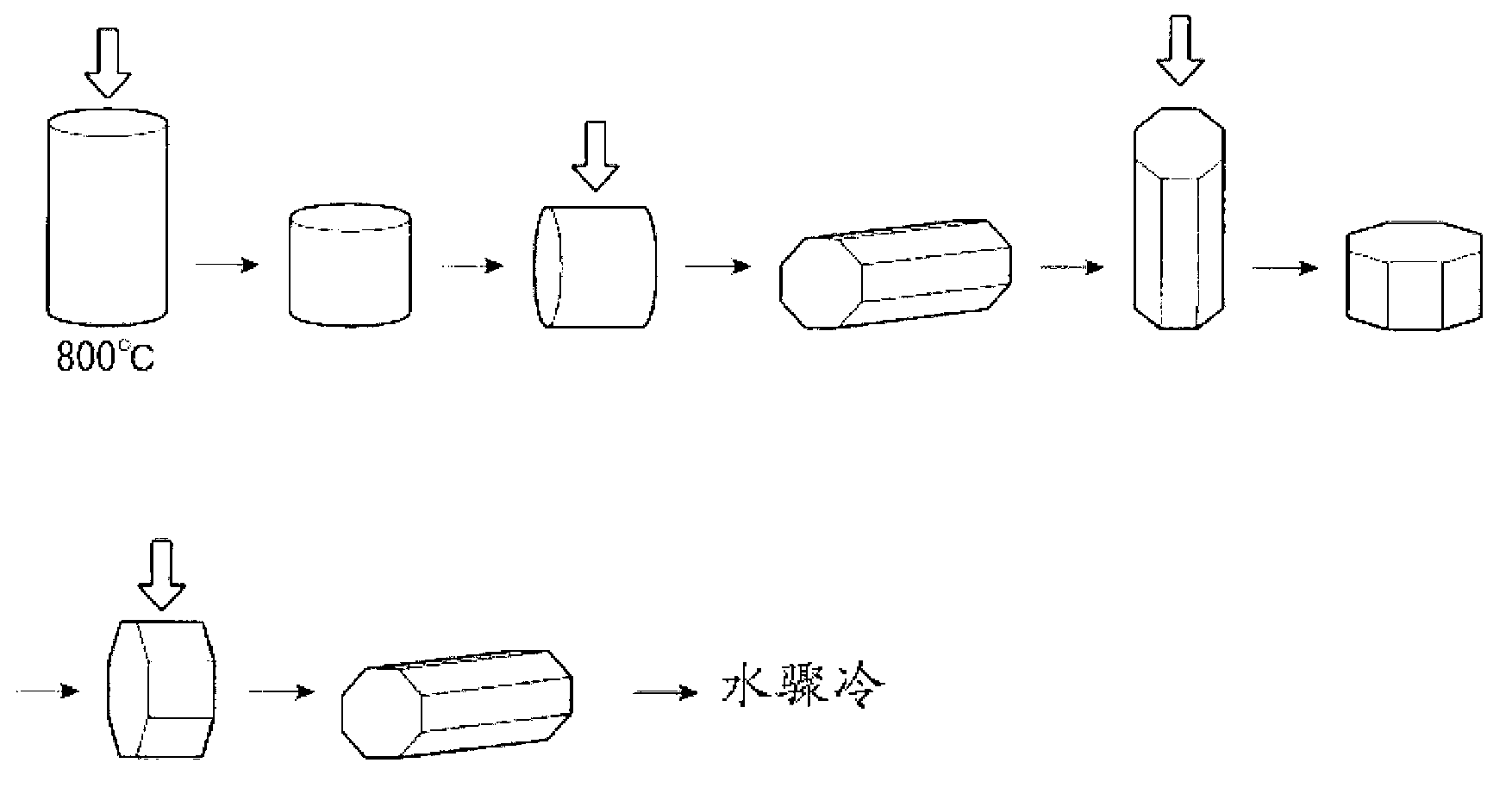

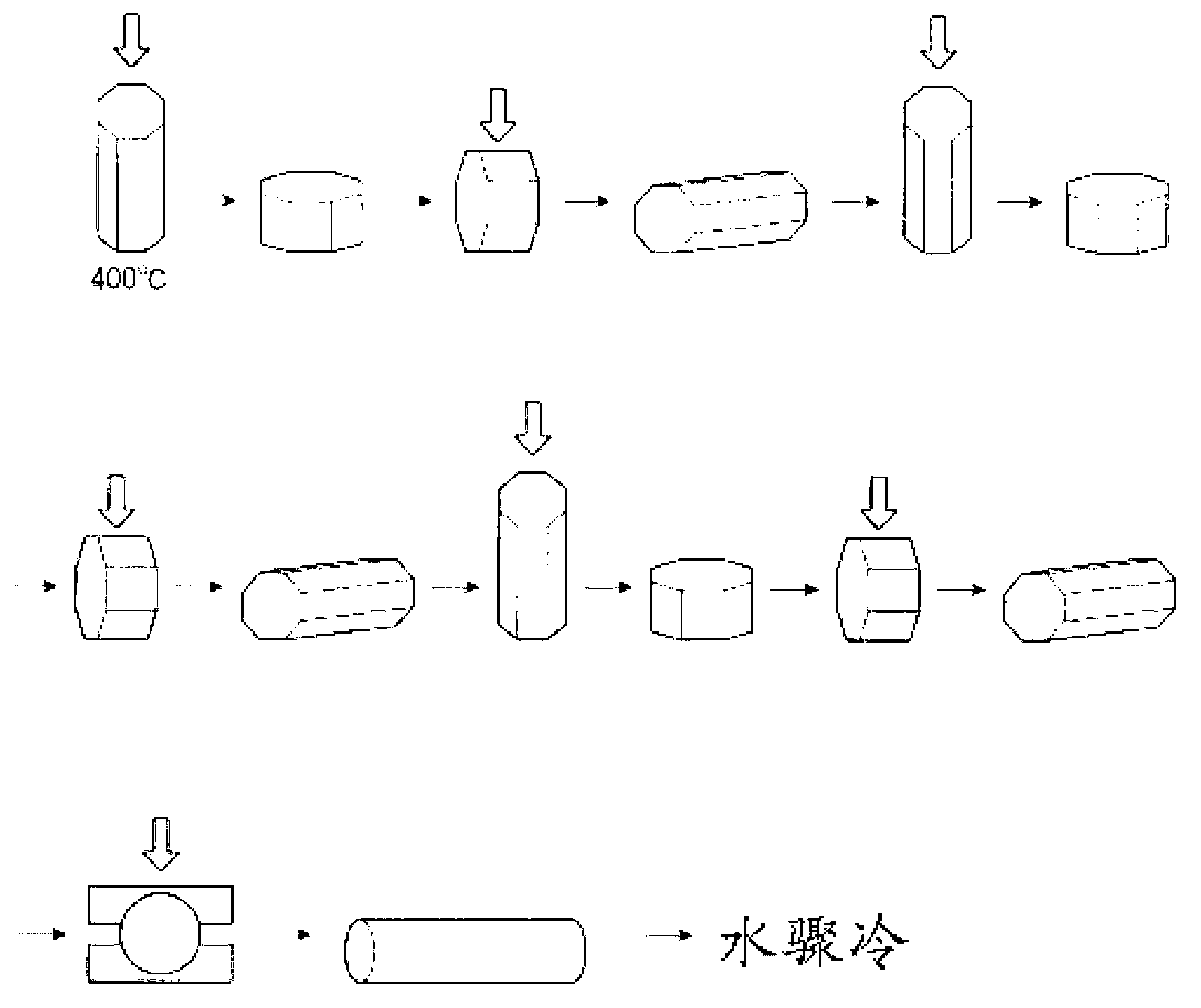

Method used

Image

Examples

Embodiment

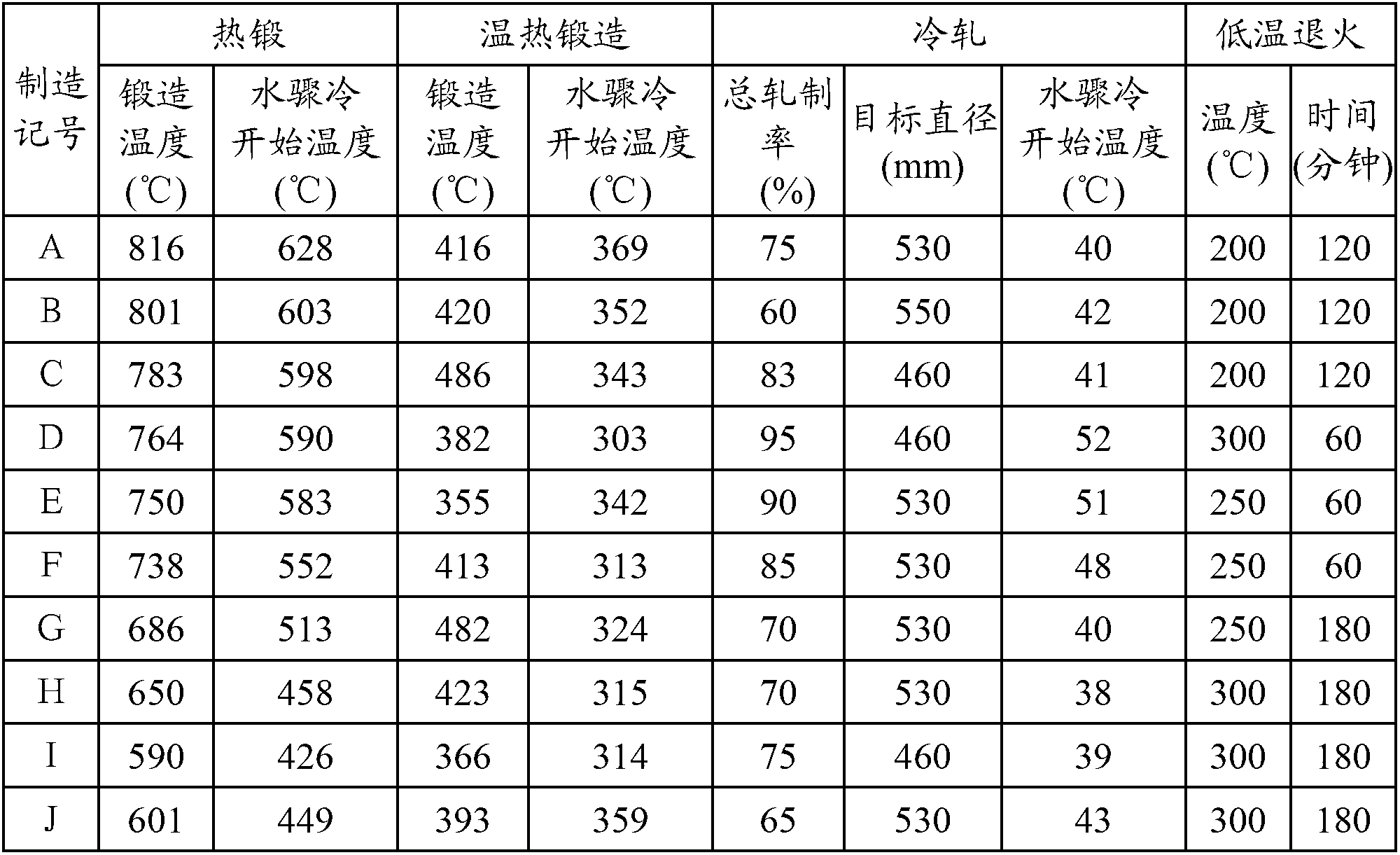

[0060] Next, the present embodiment will be specifically described by way of examples.

[0061] Manufactures high-purity copper ingots with a Cu purity of 99.9999% by mass or higher and a size of 250 mm in diameter and 600 mm in length. The high-purity copper ingots are manufactured by unidirectional solidification, in which the surface of the molten metal solidifies last in the manufacturing process. Therefore, there are no casting defects such as shrinkage cavities or voids inside the ingot, and the ingot has a sound casting structure.

[0062] As a result of measuring the size of the crystal grains of the ingot, it was found that the size of the crystal grains was 1,000 to 200,000 μm, the variation in the size of the crystal grains was large, and all the crystal grains were coarse.

[0063] Table 2 shows the measured average crystal grain size of the ingot and the deviation of the crystal grain size (=area ratio of crystal grains having a grain size larger than 2.5 times t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com