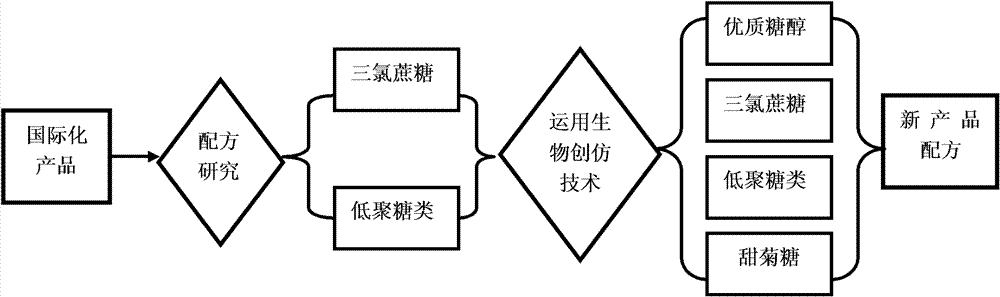

Composite health sweetener prepared by biological imitative innovation technology

A sweetener and healthy technology, applied in food science, application, food preparation, etc., can solve problems such as bad taste, pathological changes, and denaturation when heated, and achieve the effects of non-toxic side effects, prevention of high blood pressure, and food safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0038] New sweetener products, each component is calculated by weight percentage: 1%~5% sucralose, 15%~30% stevioside, 30%~35% high-quality sugar alcohol, 35%~45% oligosaccharide Among them, xylitol can be selected as high-quality sugar alcohol, and isomaltooligosaccharide can be selected as oligosaccharide, and the preferred content range of sucralose is 2%~5%.

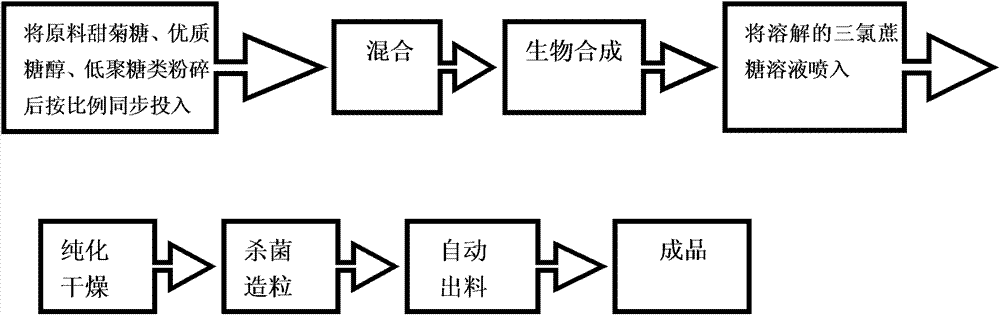

[0039] see figure 2 , the production technology of this sweetener comprises the following steps:

[0040] (1) The raw materials stevioside, high-quality sugar alcohols, and oligosaccharides are pulverized and put into special equipment for mixing, stirring evenly, so that the physical properties of the raw materials are interdependent, and the purpose is to achieve pure sweetness without destroying the physical properties of the single product;

[0041] (2) Mix sucralose with purified water, heat to dissolve, filter through a 100-mesh activated carbon filter to remove impurities, filter and store for later ...

specific Embodiment approach 2

[0047] The new sweetener product, each component is calculated by weight percentage: 2%~5% sucralose, 20%~35% stevioside, 10%~20% xylitol, 50%~60% glucose, the Sweetener products are low-sugar and low-calorie products. Through the above-mentioned production process, sweetener products are also produced from various components, so I won’t go into details here. The sweetener products produced have pure taste, high sweetness, and anti-cavity , Excellent solubility, fineness, health care, low price and safe use, also as mentioned above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com