Hard alloy and preparation method thereof

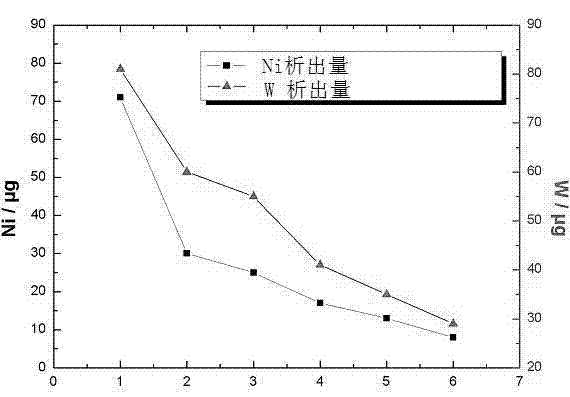

A cemented carbide and alloy technology, applied in the field of cemented carbide, can solve the problems such as the unsatisfactory precipitation of product elements, and achieve the purpose of inhibiting aggregation and recrystallization growth, grain refinement, carburization and/or decarburization defect improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

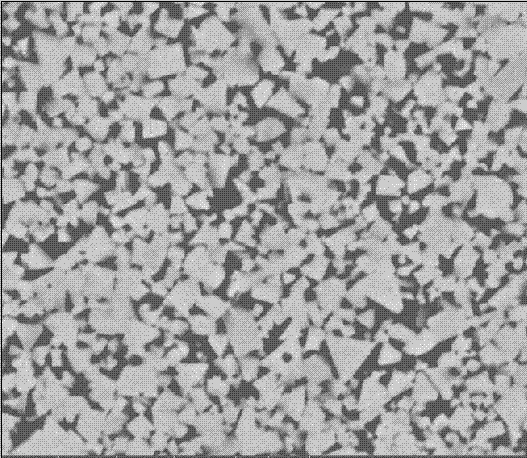

Image

Examples

Embodiment 1

[0017] A corrosion-resistant hard alloy material for drinking water systems and a preparation method thereof, comprising the following steps

[0018] (1) Ingredients and ball milling: Put tungsten carbide powder, -400 mesh nickel powder, -320 mesh chromium powder and -400 mesh chromium carbide powder, grinding aid, and hexane medium according to the proportioning ratio. Ball mill rolling ball milling, ball milling time 36 hours; 2 hours before the end of ball milling, add molten paraffin wax molding agent.

[0019] Proportioning parts by weight are:

[0020] Ball abrasive: 89.8 parts of tungsten carbide powder, 9 parts of nickel powder, 0.96 parts of chromium powder, 0.24 parts of chromium carbide powder;

[0021] Forming agent, grinding aid: 2 parts of paraffin wax forming agent, 0.1 part of stearic acid grinding aid;

[0022] Hexane: Add 320ml of hexane per kilogram of ball mill.

[0023] (2) Drying and granulation: Sieve the ball abrasive through a -300 mesh, dry, and sp...

Embodiment 2

[0031] A corrosion-resistant cemented carbide material for drinking water systems and a preparation method thereof, which are the same as in Example 1 except for the following steps:

[0032] (1) Ingredients and ball milling: Put tungsten carbide powder, -400 mesh nickel powder, -320 mesh chromium powder and -400 mesh chromium carbide powder, grinding aid, and hexane medium according to the proportioning ratio. Ball mill rolling ball milling, ball milling time 48 hours; 2 hours before the end of ball milling, add the paraffin wax forming agent in molten state.

[0033] Proportioning parts by weight are:

[0034] Ball abrasive: 88.5 parts of tungsten carbide powder, 10 parts of nickel powder, 1.2 parts of chromium powder, 0.3 parts of chromium carbide powder;

[0035](4) Sintering: The semi-finished product is dewaxed in a hydrogen carrier gas-low-pressure sintering integrated furnace to remove the molding agent and high-temperature pressure sintering, the sintering temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com