Method for preparing thermal reaction meat flavor by utilizing wheat gluten

A technology of wheat gluten protein and wheat gluten, which is applied in the field of food additives, can solve the problems of kidney and nervous system damage, and achieve the effects of outstanding salty and delicious taste, good color and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

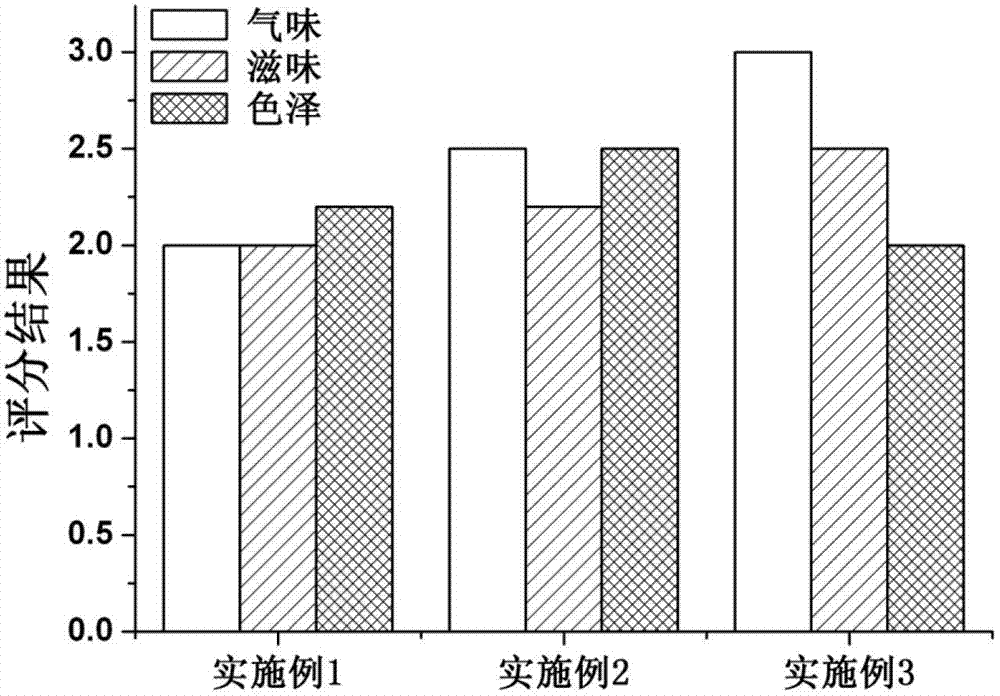

Embodiment 1

[0042]Wheat gluten was weighed, slowly added to water while stirring, and stirred at room temperature for 30 min to obtain a suspension with a substrate concentration of 100 g / L. Use 1 mol·L -1 Adjust the pH to 6.0 with NaOH or HCl solution, preheat to 55°C, add flavor protease, the enzyme to substrate mass ratio (E / S) is 1:100. The feed solution was oscillated at a constant temperature of 55°C in a shaker. After 12 hours of reaction, the enzymolysis solution was placed in a water bath at 95°C and kept for 10 minutes to inactivate the enzyme. Afterwards, it was rapidly cooled in an ice-water bath, centrifuged (3000 r / min, 20 min) to obtain the supernatant, and freeze-dried to obtain the enzymatic hydrolysis product.

[0043] Take 15 g of wheat gluten hydrolyzate, 5 g of xylose, and 1 g of L-cysteine after freeze-drying, add water to dissolve, and prepare a solution with a total solid content of 21% (w / w), stir evenly, Adjust the pH to 4.5, and react at 100°C for 60 min. A...

Embodiment 2

[0045] Wheat gluten was weighed, slowly added into water while stirring, and stirred at room temperature for 30 min to obtain a suspension with a substrate concentration of 150 g / L. Use 1 mol·L -1 NaOH or HCl solution to adjust the pH to 6.0, preheat to 55°C, add flavor protease, E / S is 1.5:100. The feed solution was oscillated at a constant temperature of 55°C in a shaker. After 10 hours of reaction, the enzymolysis solution was placed in a water bath at 95°C and kept for 10 minutes to inactivate the enzyme. Afterwards, it was rapidly cooled in an ice-water bath, centrifuged (4000 r / min, 15 min) to obtain the supernatant, and freeze-dried to obtain the enzymatic hydrolysis product.

[0046] Take 15 g of wheat gluten hydrolyzate, 5 g of glucose, and 1 g of L-cysteine after freeze-drying, dissolve them in water, and prepare a solution with a total solid content of 21% (w / w), stir well, adjust The pH was 5, and the reaction was carried out at 100°C for 90 min. After the rea...

Embodiment 3

[0048] Wheat gluten was weighed, slowly added into water while stirring, and stirred at room temperature for 30 min to obtain a suspension with a substrate concentration of 100 g / L. Use 1 mol·L -1 Adjust the pH to 6.0 with NaOH or HCl solution, preheat to 55°C, add flavor protease and complex protease in equal proportions, E / S is 1:50. The feed solution was oscillated at a constant temperature of 55°C in a shaker. After reacting for 6 hours, the enzymolysis solution was placed in a water bath at 95°C and kept for 10 minutes to inactivate the enzyme. Afterwards, it was rapidly cooled in an ice-water bath, centrifuged (5000 r / min, 10 min) to obtain the supernatant, and freeze-dried to obtain the enzymatic hydrolysis product.

[0049] Take 15 g of wheat gluten hydrolyzate, 5 g of xylose, 1 g of L-cysteine, V C 0.25 g and 0.75 g of NaCl were dissolved in water to prepare a solution with a total solid content of 22% (w / w), stirred evenly, adjusted to pH 4, and reacted at 100°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com