Partially absorbed herniorrhaphy patch

A hernia repair and negative film technology, applied in the field of hernia repair sheets, can solve the problems of inability to use hernia repair materials, inability to process, and damage to surrounding tissues, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

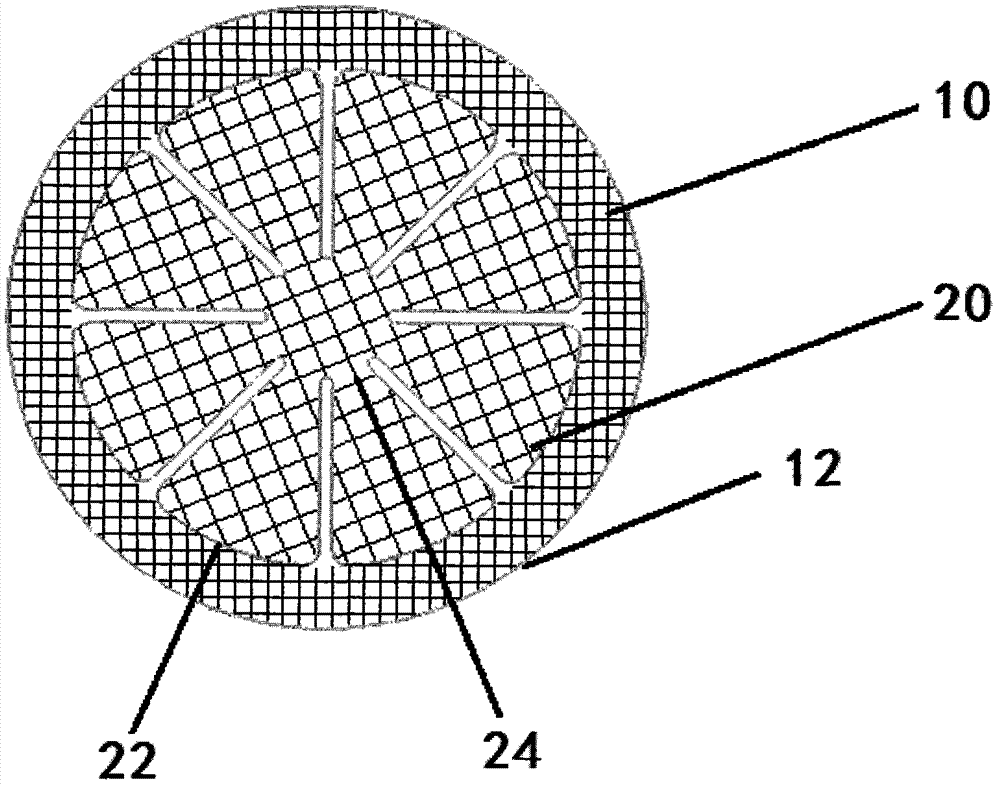

[0034] as attached figure 1 As shown, the hernia repair sheet described in this embodiment is composed of a mesh bottom sheet 10 and petals 20 . In this embodiment, the mesh backsheet 10 has a circular profile, is made of a mesh weave, and has a single-layer structure. Eight petals 20 are fixed on the upper surface of the mesh bottom sheet 10 , the far ends 22 of which are free and can move freely, and the proximal end 24 is fixed at the central area of the mesh bottom sheet 10 . The circular periphery of the central area is schematic and does not imply that such a clear boundary actually exists, and its purpose is only to illustrate the approximate location of the central area. The distal ends 22 of the petals 20 are at a distance from the periphery 12 of the mesh backsheet 10 . According to needs, the distance between the distal end 22 of the petal 20 and the outer periphery 12 of the net-shaped bottom sheet 10 can be changed, can be smaller, can be larger, can be roughl...

Embodiment 2

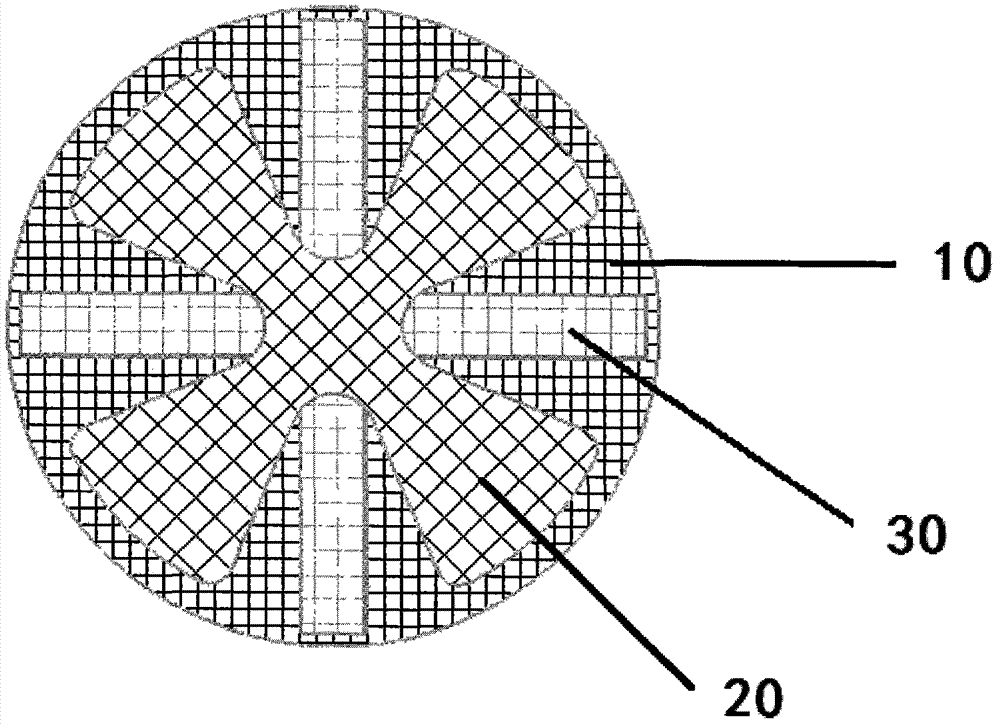

[0036] as attached figure 2 As shown, the patch of this embodiment includes four integrally formed petals 20 and an integrally formed cross-shaped reinforcing rib 30 , and the four petals 20 are symmetrically arranged radially around the center of the circular mesh base 10 . The petals 20 and the reinforcing ribs 30 are connected together at the central area of the mesh bottom sheet 10 and fixed by welding at the center of the mesh bottom sheet 10 . The mesh bottom sheet 10, the petals 20 and the ribs 30 are made of the same mesh porous braid. The distal ends of the reinforcing ribs 30 are fixed to the vicinity of the outer periphery of the mesh backsheet 10 by sewing only near the end points. Welding or sewing can be used for fixing. There is not much difference in effect between the two methods. When welding is used, the appearance is relatively smooth and beautiful, and it is easy to be accepted by doctors and patients, but there is a view that the structure and / or me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com