Treatment method of polymer flooding and binary combination flooding-SP-sewage

A technology of binary compound flooding and treatment method, applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. Problems such as large, increased consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

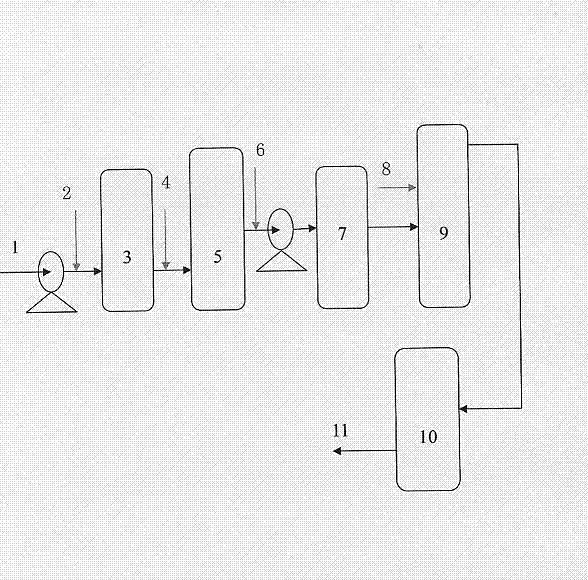

Method used

Image

Examples

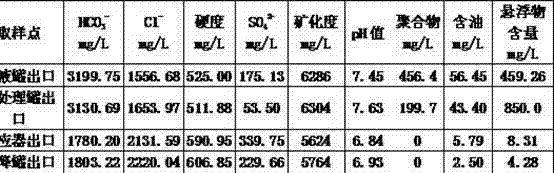

Embodiment 1

[0020] The polymer content of the test sewage was 257 mg / L, and the pretreatment agent 1 was industrial ferrous sulfate (FeSO 4 ·7H 2 O), add 30 mg / L, after an interval of 15s, add pretreatment agent 2 as industrial ammonium persulfate ((NH 4 ) 4 S 2 o 8 ), add an amount of 30 mg / L, stir well and then let it stand for 1 hour to react; add coagulant 1000 mg / L (based on the effective content of aluminum sulfate) under rapid stirring conditions (G value is 350s-1), and react for 1.5 After 1 min, add flocculant (partially hydrolyzed polyacrylamide) 8 mg / L, continue to react under stirring conditions for 1.5 min, stop stirring, let it settle for 10 min, take the middle clear liquid for water quality testing, the concentration of suspended solids in water is 5.00 mg / L, oil content 3.76 mg / L;

[0021] The coagulant of the test is prepared in parts by weight: add 200 parts of aluminum sulfate to 780 parts of tap water under stirring conditions, add 20 parts of polydimethyldially...

Embodiment 2

[0024] The polymer content of the test sewage is 471mg / L, and the pretreatment agent 1 is industrial ferrous sulfate (FeSO 4 ·7H 2 O), the dosage is 50 mg / L, and the pretreatment agent 2 is added after an interval of 15s, which is industrial ammonium persulfate ((NH 4 ) 4 S 2 o 8 ), add an amount of 50 mg / L, stir evenly and let it stand for 1 hour to react; add coagulant 1500 mg / L (based on the effective content of aluminum sulfate) under rapid stirring conditions (G value is 350s-1), and react for 1.5 After 1 min, add flocculant (partially hydrolyzed polyacrylamide) 8 mg / L, continue to react under stirring conditions for 1.5 min, stop stirring, let it settle for 10 min, take the middle clear liquid for water quality testing, the concentration of suspended solids in water is 4.50 mg / L, oil content 3.95 mg / L;

[0025] The coagulant used is prepared in parts by weight: add 200 parts of aluminum sulfate to 780 parts of tap water under stirring conditions, add 20 parts of po...

Embodiment 3

[0028] The polymer content of the test sewage was 790mg / L, and the pretreatment agent 1 was industrial ferrous sulfate (FeSO 4 ·7H 2 O), the dosage is 50 mg / L, and the pretreatment agent 2 is added after an interval of 15s, which is industrial ammonium persulfate ((NH 4 ) 4 S 2 o 8 ), adding an amount of 50 mg / L, stirring evenly and standing for 1 hour to react; under rapid stirring conditions (G value 350s-1), adding coagulant 1000 mg / L (based on the effective content of polyaluminium chloride), After reacting for 1.5 minutes, add flocculant (partially hydrolyzed polyacrylamide) 8 mg / L, continue to react under stirring conditions for 1.5 minutes, stop stirring, let it settle for 10 minutes, take the middle clear liquid for water quality testing, and the concentration of suspended solids in the water is 2.00 mg / L, oily 2.18 mg / L;

[0029] The coagulant of test is prepared in parts by weight: under agitation, 200 parts of polyaluminum chloride are added to 460 parts of tap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com