Recyclable red brick sand premixed dry mortar and manufacturing method thereof

A technology of dry powder mortar and a manufacturing method, applied in the field of building material concrete, can solve the problems of difficult control of fluidity of structural concrete, limited application, high porosity and high water absorption rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below, the present invention will be described in further detail in combination with specific implementation examples.

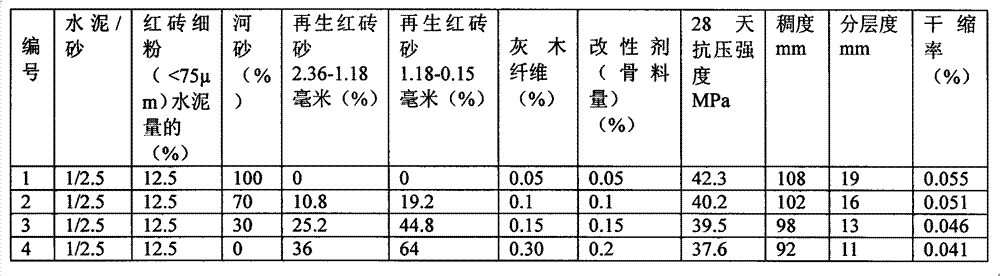

[0038] Implementation example 1

[0039] It can be seen from the ratios listed in Table 1 and the characteristics of the produced dry-mixed mortar that the strength of the mortar has decreased due to the increase in the amount of recycled red brick sand, but the strength of all dry-mixed mortars still reaches above 35MPa, fully reaching the Requirements for strength in national standards. Due to the addition of wood fibers, the drying shrinkage of the dry powder mortar is much lower than 0.06%, and the consistency and layering degree meet the requirements of the national standard for masonry mortar and plastering mortar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com