A water-permeable material using desert sand as aggregate, its preparation method and application

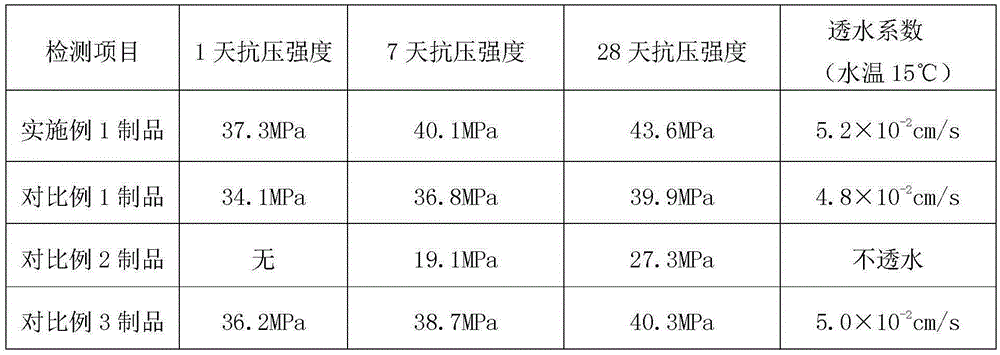

A water-permeable material and desert technology, which is applied in the field of building materials, can solve the problems of being unable to be widely promoted, low compressive strength, and high cost of permeable bricks, and achieve good water permeability, improved mechanical properties, and low prices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Accurately weigh raw materials (Kg): Kubuqi desert sand 85, Portland cement 5, water glass 5, water-based epoxy resin binder 3, polyvinyl acetate binder 1, coloring agent molybdenum chrome scarlet 1.

[0025] Preparation:

[0026] (a) Add desert sand, inorganic binder and colorant to the cement mortar mixer and stir evenly;

[0027] (b) Add water-based polymer binder and stir evenly;

[0028] (c) injecting the stirred raw materials into the mould;

[0029] (d) Use the pressurized belt vibration forming process to ensure that the new water-permeable material is formed, maintain it at room temperature for 24 hours, and then demould.

[0030] The novel water-permeable material is used for preparing water-permeable pavement permeable bricks.

[0031] Water-based epoxy resin binder, preferably bisphenol A type epoxy resin, such as bisphenol A type epoxy resin E-44, E-42, E-35, E-31, E-20, E-14, E One of -12, E-06, E-03 or any combination thereof.

Embodiment 2

[0042] Accurately weigh raw materials (Kg): Kubuqi desert sand 80, water-based epoxy resin 3, Portland cement 2, water glass 1, medium chrome yellow 1.

[0043] Preparation:

[0044] (a) Add desert sand, portland cement, water glass and colorant to the cement mortar mixer and stir evenly;

[0045] (b) Add water-based polymer binder and stir evenly;

[0046] (c) injecting the stirred raw materials into the mould;

[0047] (d) Use the pressurized belt vibration forming process to ensure that the new water-permeable material is formed, maintain it at room temperature for 24 hours, and then demould.

[0048] The novel water-permeable material is used for preparing water-permeable pavement permeable bricks.

[0049] Water-based epoxy resin binder, preferably bisphenol A type epoxy resin, such as bisphenol A type epoxy resin E-44, E-42, E-35, E-31, E-20, E-14, E One of -12, E-06, E-03 or any combination thereof.

Embodiment 3

[0051] Accurately weigh raw materials (Kg): Kubuqi desert sand 90, water-based epoxy resin 3, polyvinyl acetate resin 3, Portland cement 8, molybdenum chromium scarlet 2.

[0052] Preparation:

[0053] (a) Add desert sand, portland cement and colorant to the cement mortar mixer and stir evenly;

[0054] (b) Add water-based epoxy resin and polyvinyl acetate resin and stir evenly;

[0055] (c) injecting the stirred raw materials into the mould;

[0056] (d) Use the pressurized belt vibration forming process to ensure that the new water-permeable material is formed, maintain it at room temperature for 24 hours, and then demould.

[0057] The novel water-permeable material is used for preparing water-permeable pavement permeable bricks.

[0058] Water-based epoxy resin binder, preferably bisphenol A type epoxy resin, such as bisphenol A type epoxy resin E-44, E-42, E-35, E-31, E-20, E-14, E One of -12, E-06, E-03 or any combination thereof.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com