Trichloroethylene gas phase catalysis production method

A kind of technology of trichloroethylene and production method, which is applied in the field of gas-phase catalytic production of trichloroethylene and achieves the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

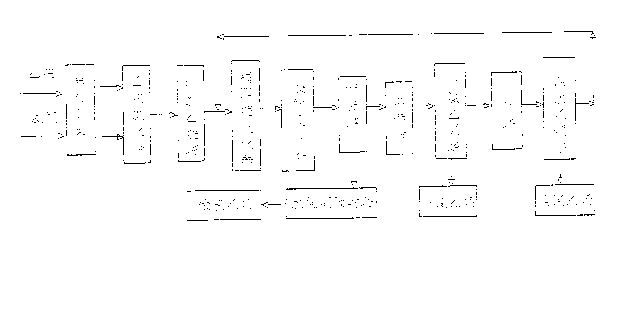

[0009] according to figure 1 As shown, after acetylene and chlorine pass through the drying process, they are sent to the acetylene chlorination tower respectively, and acetylene and chlorine are chlorinated, then vaporized through the tetrachloroethane tower and refined tetrachloroethane vaporizer, and then reacted through the cracking reactor Finally, after passing through the desorption tower and low boiling tower, it reaches the trichlorethylene tower to form a trichlorethylene product. After being treated in an intermediate tower, the material after the removal of trichlorethylene is passed into the tetrachlorethylene tower to form a tetrachlorethylene product. The mother liquor after separation of tetrachlorethylene is returned to the back of the tetrachloroethane tower to continue to participate in the reaction, and the material after the desorption tower is absorbed by the adsorption tower to absorb hydrogen chloride, and the remainder is sent to the soda plant to be us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com