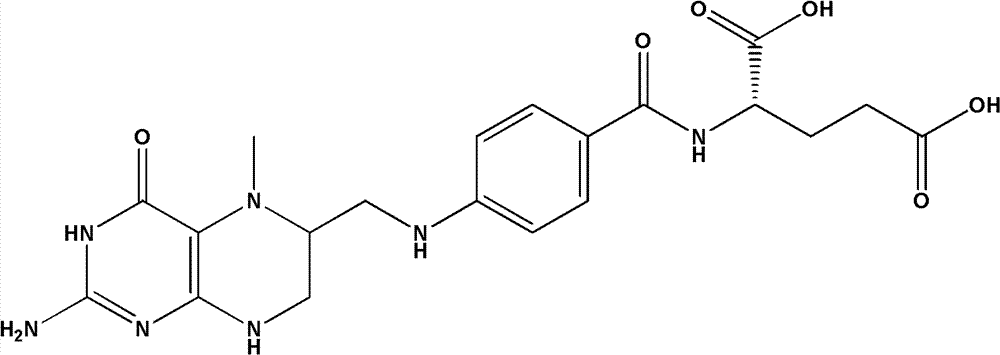

Stable 5-methyltetrahydrofolate crystal form and preparation method thereof

A technology of methyltetrahydrofolate and methyltetrahydrofolate, which is applied in the field of stable amorphous 5-methyltetrahydrofolate and its preparation, can solve the problem that the temperature control requirements are very strict, the time is long, and the operation Cumbersome and other problems, to achieve the effect of short time, good stability and simple reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

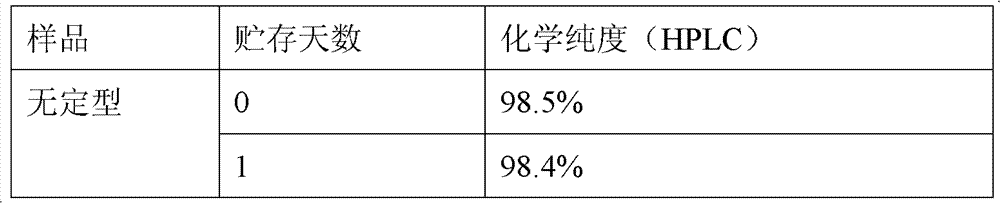

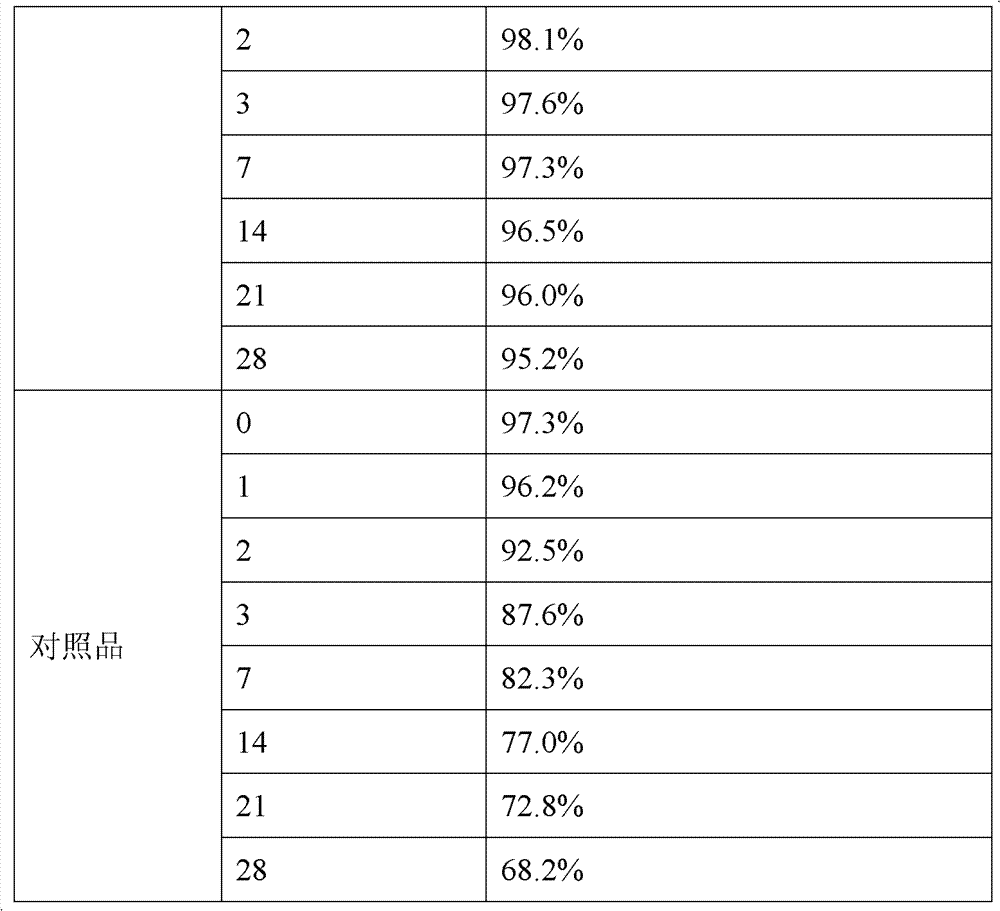

Examples

Embodiment 1

[0035] 30ml of deionized water, add 2.10 grams of (6S)-5-MTHF, neutralize with 2mol / L liquid caustic soda under stirring until the pH value is 7.0 to completely dissolve the (6S)-5-MTHF, add 10% calcium chloride solution ( Containing 0.5 grams of calcium chloride), transferred to an ultrasonic reactor with a frequency of 40KHz and a power of 500w, controlled the temperature of the solution at 15°C, ultrasonically reacted for 60 minutes, filtered, and washed. Vacuum-dried at 25° C. to obtain 1.08 g of white amorphous (6S)-5-MTHF calcium salt. The chemical purity is 98.7%.

Embodiment 2

[0037] 30ml of deionized water, add 2.10 grams of (6S)L-5-MTHF, neutralize with 2mol / L ammonia water under stirring until the pH value is 7.0 to completely dissolve the (6S)-5-MTHF, add 10% calcium chloride solution ( Containing 0.5 grams of calcium chloride), transferred to an ultrasonic reactor with a frequency of 40KHz and a power of 800w, controlled the temperature of the solution at 10°C, ultrasonically reacted for 65 minutes, filtered, and washed. Vacuum-dried at 25° C. to obtain 1.10 g of white amorphous (6S)-5-MTHF calcium salt. The chemical purity is 98.6%.

Embodiment 3

[0039] 60ml of deionized water, add 5.05 grams of (6S)-5-MTHF, neutralize with 2mol / L liquid caustic soda under stirring until the pH value is 7.5 to (6S)-5-MTHF is completely dissolved, add 10% calcium chloride solution ( Containing 1.0 grams of calcium chloride), transferred to an ultrasonic reactor with a frequency of 60KHz and a power of 500w, controlled the temperature of the solution at 5°C, ultrasonically reacted for 70 minutes, filtered, and washed. Vacuum drying at 25° C. gave 1.88 g of white amorphous (6S)-5-MTHF calcium salt. Chemical purity 98.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com