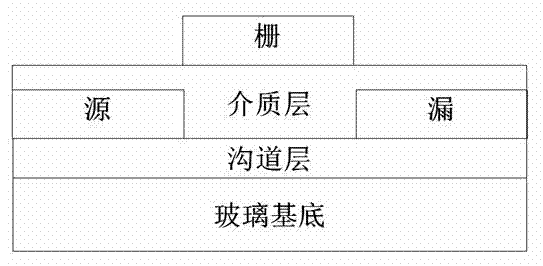

Manufacture method of thin film transistor and with indium zinc aluminum oxide as channel layer

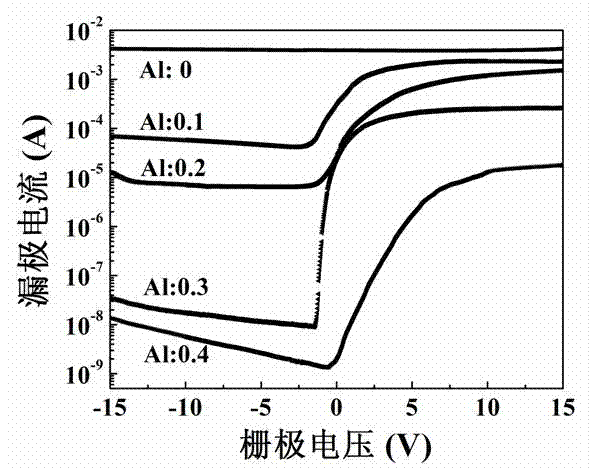

A technology of indium zinc aluminum oxide and thin film transistors, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of large off-state current of devices, and achieve the effect of simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Among the present invention, PMMA solid powder is purchased from Sigma-Aldrich company, and molecular weight is 12000.

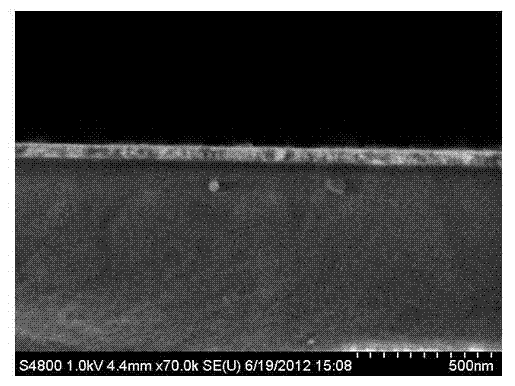

[0031] First, an indium zinc aluminum oxide film is prepared on a glass substrate as a channel layer. The specific implementation is: using ethanolamine as a stabilizer (wherein, the volume ratio of ethanolamine to ethylene glycol is 0.1:20), the analytically pure In(NO 3 ) 3 4.5H 2 O, Zn(C 2 h 3 o 2 ) 2 ·5H 2 O and AlCl 3 ·6H 2 O is dissolved in ethylene glycol and stirred at 60°C for 1 hour to form a clear and transparent precursor solution. When the precursor solution ([Al 3+ ]+ [In 3+ ]+[Zn 2+ ]) at a concentration of 0.25 M, the molar ratio of indium to zinc (In 3+ : Zn 2+ ) under the premise of 1:1, the prepared aluminum molar content is [Al] 3+ / ([In 3+ ]+[Zn 2+ ]) = 0, 0.1, 0.2 , 0.3, 0.4 of the precursor solution. After the prepared solution was left to age for 48 hours, the glass substrate was dipped for pulling coating. Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com