Graphite-containing moulded body and method for the production thereof

A molding body, graphite technology, applied in the directions of graphite, chemical instruments and methods, flange connections, etc., can solve the problems of uneven impregnation, no impregnation, uneven distribution of impregnating agents, etc., and achieve effective preparation and simple cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Expanded graphite with a bulk density of 3.5 g / l was mixed with silicone resin powder, Silres MK from Wacker Chemie AG, Burghausen, Germany, to form % silicone powder, and then mix in a container for 1 minute.

[0082] The mixture thus obtained is then transferred into a steel pipe with a diameter of 90 mm, pressed by a pressure piston by its own weight and as a density of about 0.07 g / cm 3 The preform is removed. The preform was then compressed with pressure to a desired film thickness of 1 mm, and the doped film thus obtained was subjected to conditions of 180° C. for 60 minutes in order to melt the plastic.

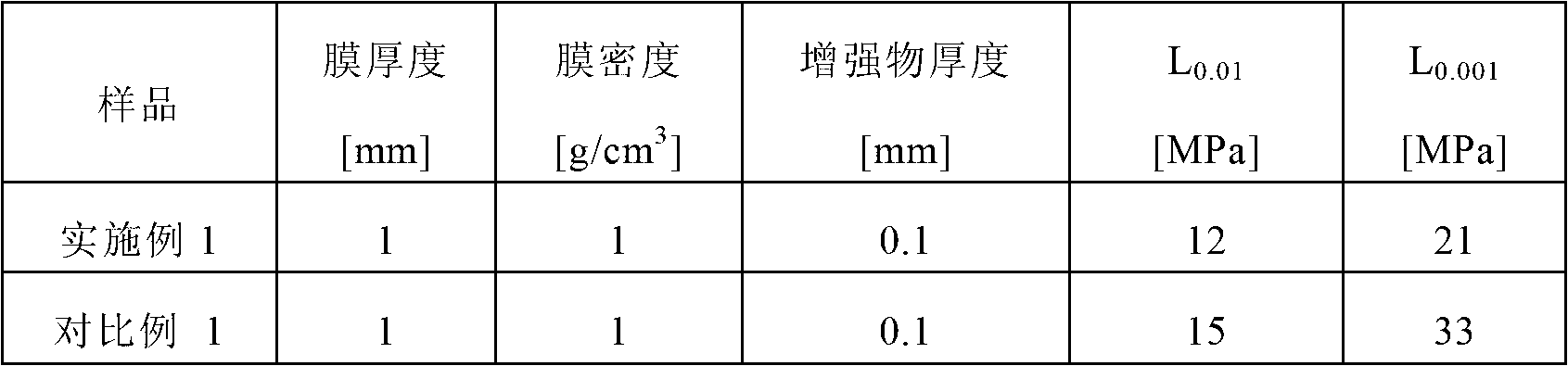

[0083] Two of these membranes were pressed with perforated plates having a thickness of 0.1 mm, and the leakage rate of the molded bodies was determined according to DIN EN 13555 using helium as test gas (40 bar internal pressure).

[0084] The specific surface pressures required to achieve specific leakage levels are given in Table 1 below.

Embodiment 2 and 3

[0093] Expanded graphite with a bulk density of 3.5 g / l was mixed with an inorganic filler, i.e. in Example 2 ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) and in Example 3 boron carbide (B4C) to form a mixture comprising 90 wt% expanded graphite and 10 wt% inorganic filler, and then mixed in a container for 1 minute.

[0094] The mixture thus obtained is then transferred into a steel pipe with a diameter of 90 mm, pressed by a pressure piston by its own weight and as a density of about 0.07 g / cm 3 The preform is removed. The preform was then compressed with pressure to a desired film thickness of 1 mm, and the doped film thus obtained was subjected to 180° C. for 60 minutes.

[0095] Nitrogen as test gas according to DIN 28090-1 and relative to 2,000g / m 2 The weight per unit area of the molded body, and the leakage rate of both samples were measured at a surface pressure of 32 MPa.

[0096] The obtained values are summarized in Table 2 below.

Embodiment 4 to 7

[0105] Expanded graphite with a bulk density of 3.5 g / l was mixed with, as inorganic filler, ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ), for Examples 6 and 7, diammonium phosphate (NH 4 ) 2 HPO 4 , to form a mixture comprising 95 wt% expanded graphite and 5 wt% inorganic filler, and then mixed in a container for 1 minute.

[0106] The mixture thus obtained is then transferred into a steel pipe with a diameter of 90 mm, pressed by a pressure piston by its own weight and as a density of about 0.07 g / cm 3 The preform is removed. The preforms were then compressed with pressure to a desired film thickness of 1 mm and the doped films thus obtained were subjected to the various conditions outlined in Table 3 below.

[0107] Nitrogen as test gas according to DIN 28090-1 and relative to 2,000g / m 2 The weight per unit area of the molded body, and the leakage rate of all samples were determined at a surface pressure of 32 MPa.

[0108] The obtained values are summarized i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com