Method for preparing peanut essence by natural thermal reaction

A technology of natural thermal reaction and peanut essence, applied in the field of natural food processing, can solve the problems of non-naturality, complex process, low yield, etc., and achieve the effects of good taste, rapid heating and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

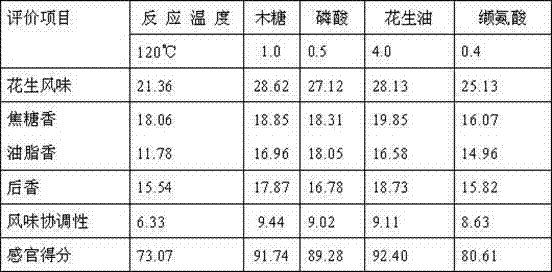

Embodiment 1

[0018] The method for preparing peanut essence by natural heat reaction is characterized in that it is prepared according to the following steps: 1. Preparation of peanut kernel enzymatic hydrolysis solution: crush peanut kernels, soak them in water for 10 minutes according to the ratio of mass percentage 1:5, and heat to Heat denaturation at 90°C for 20 minutes, and naturally cool to room temperature; 2. Add compound protease and flavor protease with a mass percentage of 4% respectively, stir evenly, place in water at 50°C for 3 hours for enzymatic hydrolysis, and obtain peanut kernel enzymatic hydrolysis solution; 2. Centrifugal filtration to obtain the filtrate; 3. Thermal reaction: add the following weight substances per 100ml filtrate to the filtrate: xylose 0.8g, valine 0.2g, phospholipid 0.5g, peanut oil 3.0g, Heat to 100-120°C in the fungus pot, keep warm for 30-50min , thus preparing Roasted peanut flavor is full-bodied, full-bodied reddish-brown pure natural liquid ...

Embodiment 2

[0020] The method for preparing peanut essence by natural heat reaction is characterized in that it is prepared according to the following steps: 1. Preparation of peanut kernel enzymatic solution: crush peanut kernels, soak them in water for 10 minutes according to the ratio of mass percentage 1:5, and heat to Heat denaturation at 90°C for 20 minutes; 2. Naturally cool to room temperature, add compound protease and flavor protease with a mass percentage of 4% respectively, stir evenly, place in water at 50°C for 3 hours for enzymatic hydrolysis, and obtain peanut kernel enzymatic hydrolysis solution: 3. Centrifugal filtration to obtain the filtrate; 4. Thermal reaction: add the following weight substances to the filtrate per 100ml filtrate: xylose 1.0g, valine 0.6g, phospholipid 0.5g, peanut oil 5.0g, in microwave assisted Microwave the heating device to heat up to 93°C, and keep it warm for 45-50 minutes to prepare a reddish-brown liquid peanut essence with a mellow, strong a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com