Method for recycling multiple elements of liquid after cyanided tailing flotation

A cyanide tailings, multi-element technology, applied in sulfur concentrate waste liquid treatment, gold smelting and cyanide tailings flotation lead, copper concentrate fields, can solve problems such as pollution, improve economic benefits and improve efficiency , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

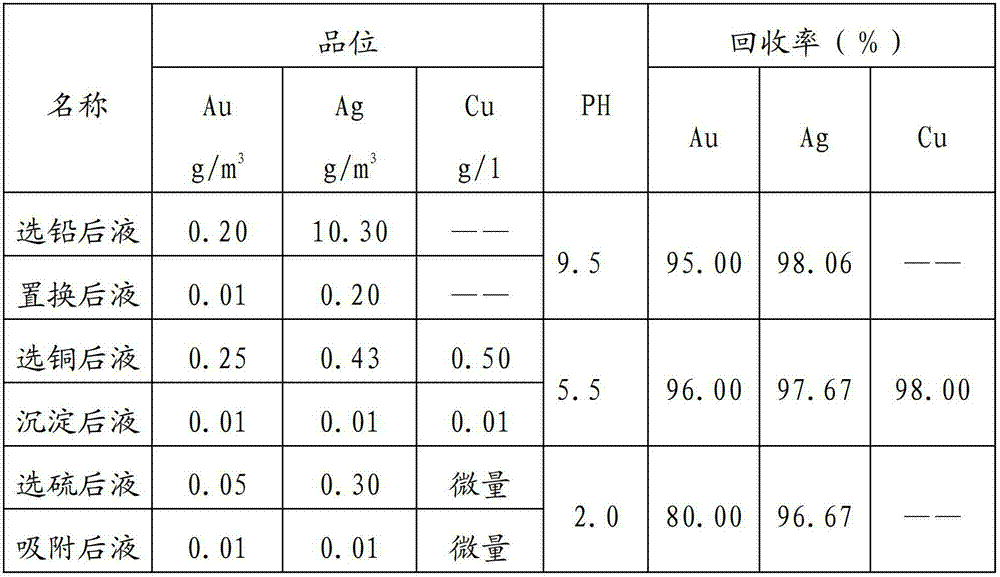

Embodiment 1

[0022] 1) Add water to the cyanidation gold extraction tailings to make it into a pulp, adjust the total mass of solute in the pulp to account for 30% of the total mass of the pulp, add lime to adjust the pH of the pulp to 9.5, use ethylsulfide as a collector, and weigh 80g / t is added to the flotation machine for closed-circuit flotation. After primary roughing, secondary closed-circuit sweeping, and secondary closed-circuit selection, lead is enriched, and lead concentrate and lead tailings are obtained through pressure filtration and dehydration. The lead-separated liquid, the lead-separated liquid and the lead-separated tailings are treated separately;

[0023] 2) Filter the lead-selected liquid to remove suspended minerals and insoluble particles in the lead-selected liquid, and obtain precipitates through the zinc powder replacement process (in the precipitates, the gold content is greater than 1% of the total mass of the precipitates %, the silver content is greater tha...

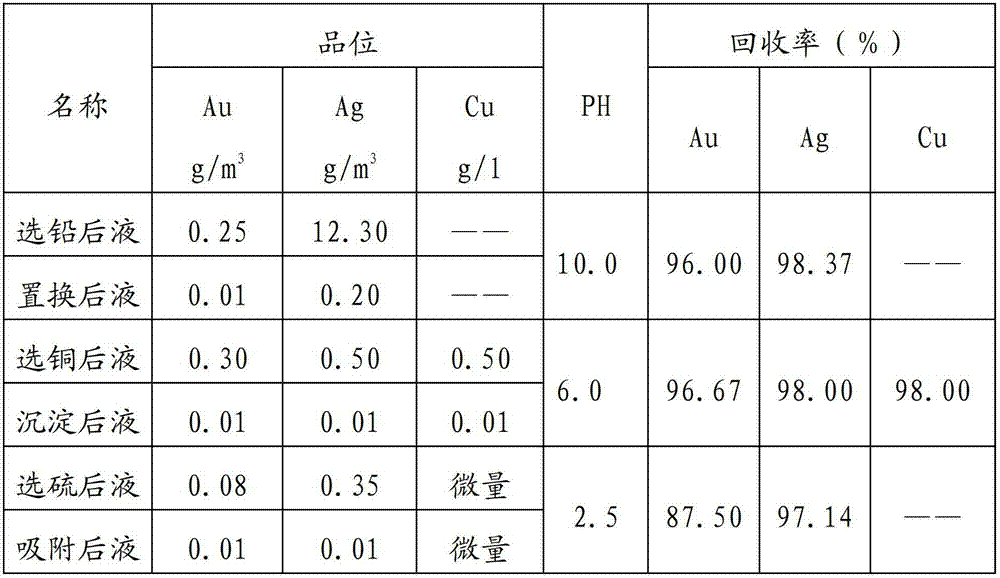

Embodiment 2

[0031] 1) Add water to the cyanidation gold extraction tailings to make it into a pulp, adjust the total mass of solute in the pulp to account for 33% of the total mass of the pulp, add lime to adjust the pH of the pulp to 10, and use isopentyl xanthate as a collector, Add 90g / t into the flotation machine for closed-circuit flotation. After first-level roughing, second-level closed-circuit sweeping, and second-level closed-circuit selection, lead is enriched, and lead concentrate and lead tailings are obtained through pressure filtration and dehydration. Ore and lead-separated liquid, lead-separated liquid and lead-separated tailings are treated separately;

[0032]2) Filter the lead-selected liquid to remove suspended minerals and insoluble particles in the lead-selected liquid, and obtain precipitates through the zinc powder replacement process (in the precipitates, the gold content is greater than 1% of the total mass of the precipitates %, the silver content is greater tha...

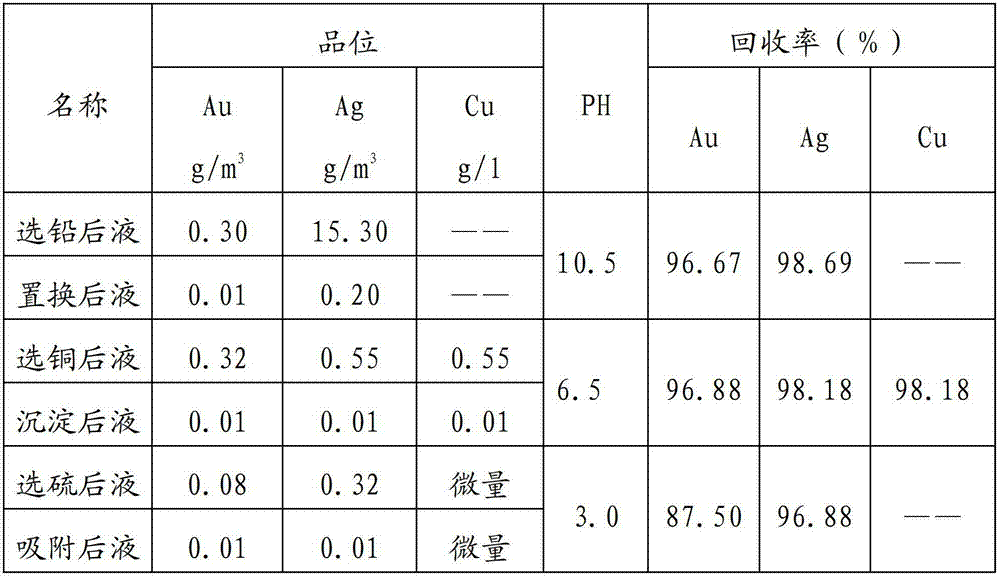

Embodiment 3

[0040] 1) Add water to the cyanidation gold extraction tailings to make it into a pulp, adjust the total mass of solute in the pulp to account for 35% of the total mass of the pulp, add lime to adjust the pH of the pulp to 11.5, and use ethyl disulfide as a collector, according to 120g / t is added to the flotation machine for closed-circuit flotation. After primary roughing, secondary closed-circuit sweeping, and secondary closed-circuit selection, lead is enriched, and lead concentrate and lead tailings are obtained through pressure filtration and dehydration. The lead-separated liquid, the lead-separated liquid and the lead-separated tailings are treated separately;

[0041] 2) Filter the lead-selected liquid to remove suspended minerals and insoluble particles in the lead-selected liquid, and obtain precipitates through the zinc powder replacement process (in the precipitates, the gold content is greater than 1% of the total mass of the precipitates %, the silver content is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com