Method for welding built-in Ni-based high-temperature alloy pipe of C/C composite material

A technology of composite materials and high-temperature alloys, applied in the direction of welding/cutting media/materials, welding media, welding equipment, etc., can solve the problems of high structural assembly requirements, low cooling and heat conduction efficiency, and achieve reliable welding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

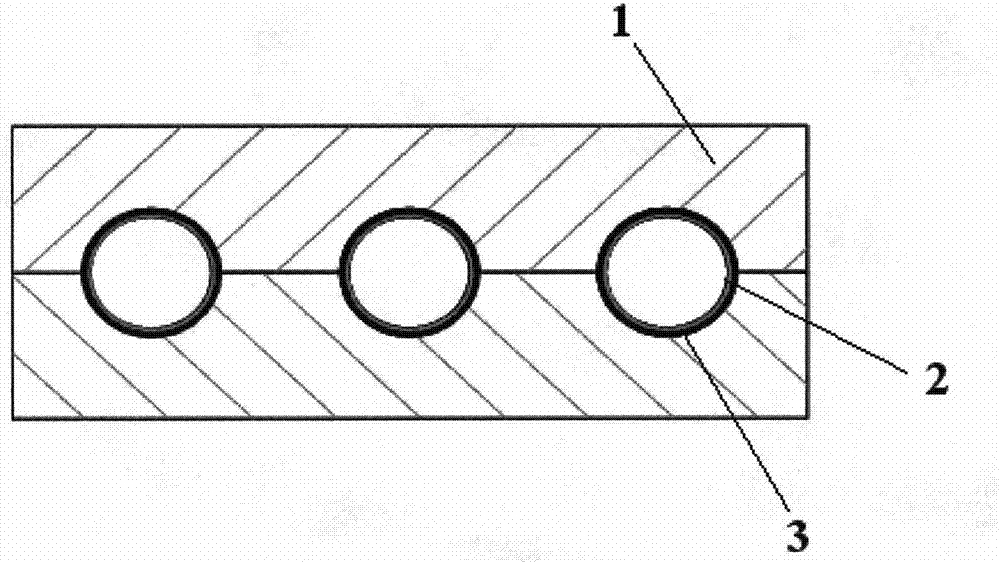

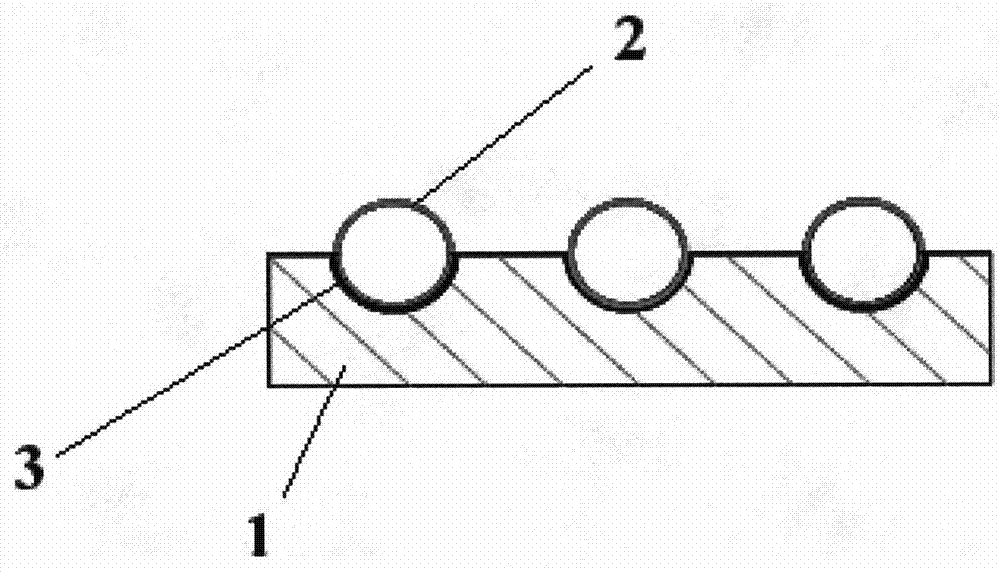

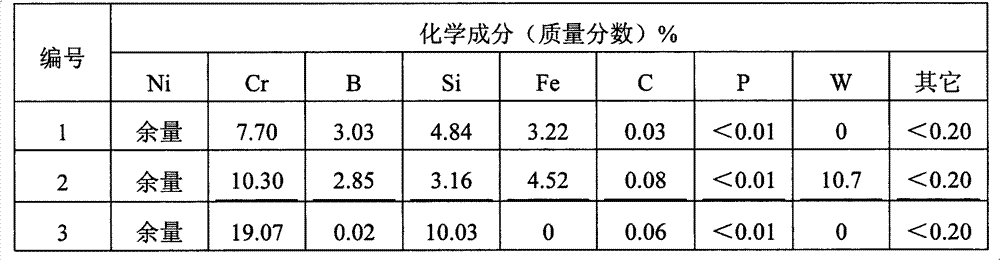

[0019] The size of the C / C composite material is 30×30×10mm, and the C / C composite material is two pieces; the Ni-based superalloy tube is GH600, the wall thickness is 1mm, the diameter is 6.0mm, and the length is 30mm; brazing materials include brazing Material and bonding agent; mix the solder and bonding agent to obtain the brazing material. The composition of the solder is selected from the No. 1 solder in Table 1, and the volume ratio of the solder to the bonding agent is 1:3; The agent is a nitrocellulose solution; the mass content of nitrocellulose in the nitrocellulose solution is 4%, the mass content of ethanol is 20%, and the mass content of ether is 76%;

[0020] 1) Three grooves are cut along the length of the surface of two C / C composite materials. The shape of the grooves is semi-cylindrical. The length of the groove is consistent with the width of the C / C composite material. The radius of the groove is 3.0~3.1. mm; the center distance between each slot is 7mm;

[00...

Embodiment 2

[0026] The size of C / C composite material is 30×30×10mm; the Ni-based superalloy tube is GH600, the wall thickness is 1mm, the diameter is 6.0mm, and the length is 30mm; the brazing material includes brazing filler metal and adhesive; the brazing filler metal Mix with the adhesive to obtain the brazing material. The composition of the brazing filler metal is selected from the No. 2 brazing filler metal in Table 1. The volume ratio of the brazing filler metal to the binder is 1:4; the binder is a nitrocellulose solution; a nitrocellulose solution The mass content of nitrocellulose is 6%, the mass content of ethanol is 24%, and the mass content of ether is 70%;

[0027] 1) Three grooves are cut along the length of the C / C composite material. The shape of the grooves is semi-cylindrical. The length of the groove is the same as the width of the C / C composite material. The radius of the groove is 3.0~3.1mm; The center distance between the slots is 9mm;

[0028] 2) Grind the surface of ...

Embodiment 3

[0033] The size of C / C composite material is 8mm×5mm×5mm; the size of GH600 is 8mm×5mm×5mm; the brazing material includes brazing material and adhesive; the brazing material is obtained by mixing the brazing material and the adhesive. The composition of the solder is selected from the No. 3 solder in Table 1. The volume ratio of solder to the bonding agent is 1:5; the bonding agent is nitrocellulose solution; the mass content of nitrocellulose in the nitrocellulose solution is 6%. The mass content is 24%, and the mass content of ether is 70%;

[0034] 1) Grind the surface of GH600 with 600#SiC sandpaper, clean the GH600 and C / C composite material with ultrasonic + acetone for 30 minutes, and leave it to air dry;

[0035] 2) Coat the brazing material on the surface of the C / C composite material and the surface of the GH600, the thickness of the brazing material is 0.2mm; then place the side of the GH600 coated with the brazing material on the C / C composite material coating There is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com