Circulating water processing method

A treatment method and circulating water technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of long treatment cycle and unstable treatment effect, and achieve easy operation , Avoid equipment corrosion, low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] This embodiment is used to illustrate the treatment method of circulating water provided by the present invention.

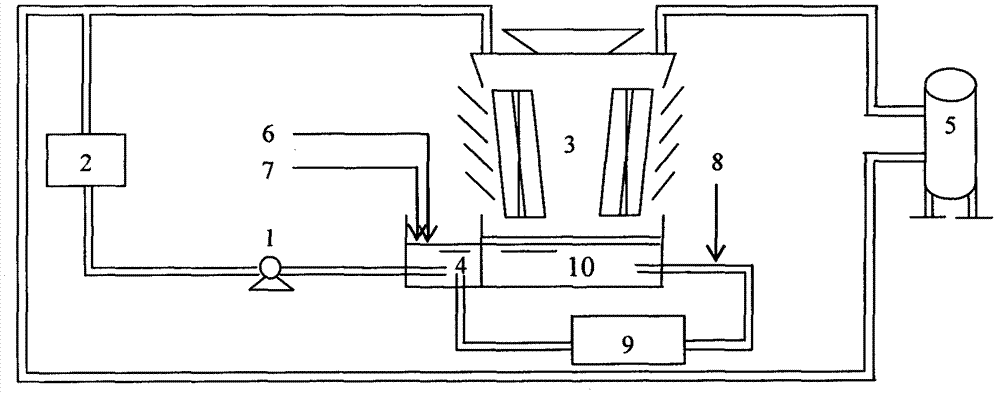

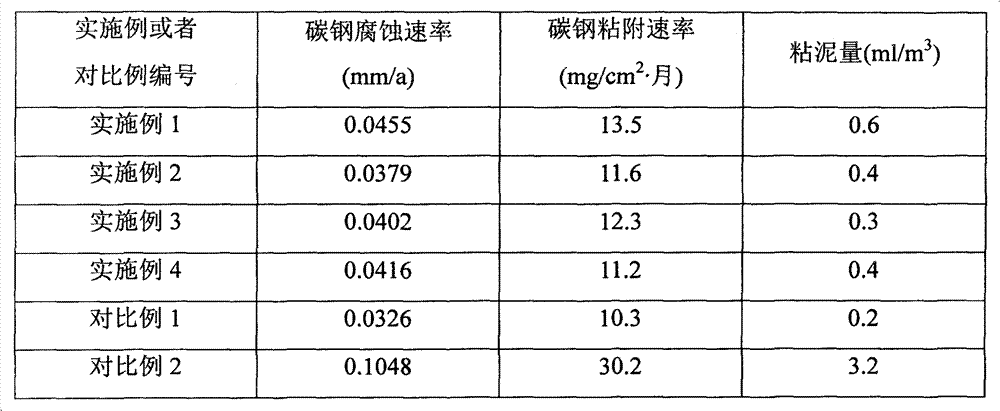

[0052] Such as figure 1 As shown, a bypass is installed on the right side of the tower pool 10 at the bottom of the cooling tower 3, and the bypass includes a pipeline and an oil-water separator 9 (swirl oil-water separator), and after realizing oil-water separation, circulating water is reintroduced in the tower pool 10 (introduce the treated circulating water near the water outlet of the suction well 4), the treatment capacity of the bypass equipment is 200L / h. The water pump 1 supplies the circulating water in the suction well 4 to the water user 2, and the circulating water after heat exchange in the cooling tower 3 re-enters the tower pool 10; mg / L. After the circulating water system runs for 100 hours, add gasoline, diesel oil and residual oil mixed oil product 3000mg / L (the weight ratio of gasoline, diesel oil and residual oil is 2: 2: 1) to the ...

Embodiment 2

[0055] This embodiment is used to illustrate the treatment method of circulating water provided by the present invention.

[0056] The circulating water is processed according to the method of Example 1, the difference is that the oil-water separator 9 is a dissolved air flotation machine, and after running for 100h, the mixed oil product 200mg / L (diesel oil and residue) is added to the circulating water in the circulating water. The weight ratio of the oil is 1:1), simulate the situation of oil leakage at the end of the water user, and close the filter 5. After adding the mixed oil, the turbidity of the circulating water increases, and the water surface can be covered with yellow-brown oil stains. The cooling tower pool , flowmeter, etc. have uneven adhesion of oil. After 12h, add degreasing agent (10 grams of dodecyldimethylbenzyl ammonium chloride, 10 grams of tetradecyldimethylbenzyl ammonium chloride, 15 grams of N, N-dimethylbenzyl ammonium chloride, Methyldodecylamine,...

Embodiment 3

[0059] This embodiment is used to illustrate the treatment method of circulating water provided by the present invention.

[0060] Process circulating water according to the method of embodiment 1, difference is:

[0061] The degreaser is a mixture of 20 grams of dodecyldimethylbenzyl ammonium chloride, 20 grams of N, N-dimethyldodecylamine, 40 grams of ethanol myristylamide and 20 grams of water.

[0062] In addition, when the turbidity of the circulating water no longer increases after adding the degreasing agent, part of the circulating water is drawn out through the bypass (the drawn amount accounts for 10% by weight of the total circulating water), and at 35°C, add Flocculant 8 (sodium carboxymethyl cellulose), and open the cyclone oil-water separator 9 for oil-water separation, it can be seen that the oil outlet of the cyclone separator flows out yellow-black oil, and the amount of flocculant and the flocculation time make the oil-water separation The turbidity of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com