Low dielectric and high heat-resistant epoxy resin composition and its preparation method

A technology of epoxy resin and composition, applied in chemical instruments and methods, layered products, metal layered products, etc., can solve limitations, poor fluidity, can not meet high frequency, high speed, high heat resistance, low dielectric Low loss and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

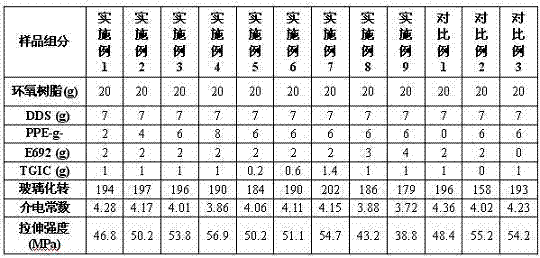

Examples

Embodiment 1

[0021] Example 1: Put 20g of epoxy resin, 2g of diluent and 2g of polyphenylene ether grafted maleic anhydride into a three-necked flask in turn, and heat it slowly to 130°C in an oil bath by mechanical stirring. After the mixed solution is stirred evenly, keep it warm for 1 hour, add 1g of TGIC, stir for 10 minutes to dissolve, cool to 100°C, then slowly add 7g of curing agent DDS into the solution, stir for 20 minutes, put it in a vacuum oven at 100°C to vacuumize and defoam After 30 minutes, pour the defoamed solution into a preheated polytetrafluoroethylene mold and put it in an oven for curing. The curing process is 140°C / 0.5h+170°C / 2h+210°C / 2h.

Embodiment 2

[0022] Example 2: Following the steps of Example 1, the amount of polyphenylene ether was changed to 20% of the epoxy resin (weight ratio, the same below).

Embodiment 3

[0023] Example 3: According to the steps of Example 1, the amount of polyphenylene ether was changed to 30% of the epoxy resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com