Reaction system for countercurrent continuous esterification of biodiesel

A technology of biodiesel and esterification reaction, which is applied in the direction of biofuel, fatty acid esterification, petroleum industry, etc., can solve the problems of incomplete esterification, non-continuous production, high energy consumption, etc., achieve complete and rapid reaction, and shorten the reaction time Time and energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

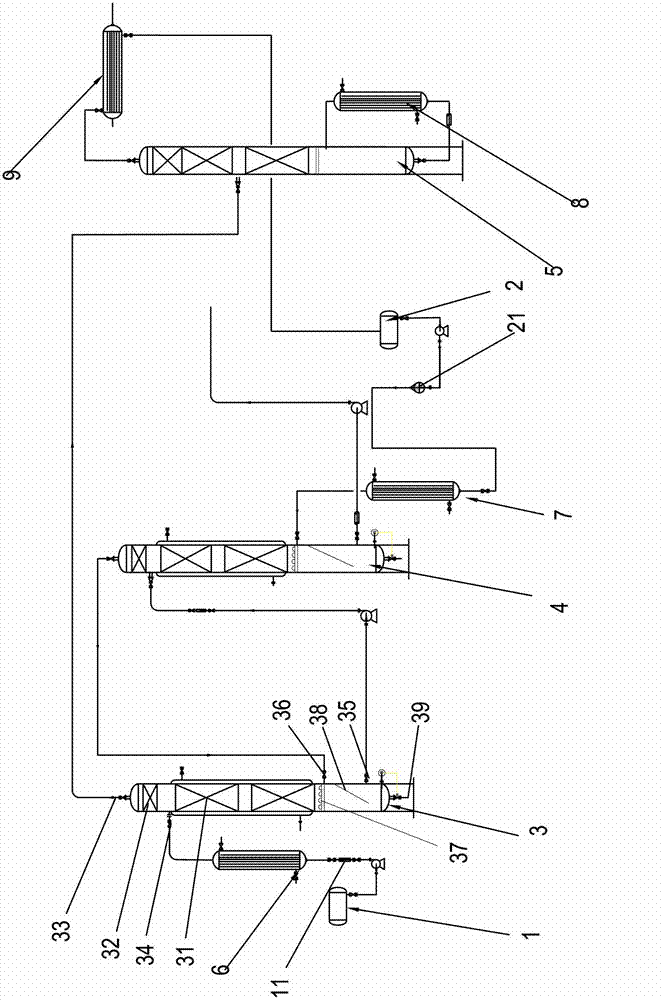

[0027] For specific embodiments of the present invention, refer to figure 1 , Biodiesel countercurrent continuous esterification reaction system, including raw material storage tank 1, methanol storage tank 2, first reaction tower 3, second reaction tower 4, methanol rectification tower 5, heaters 6, 7, 8, etc.

[0028] The top of the first reaction tower 3 is provided with a material inlet 34 and a methanol outlet 33 , and the bottom is provided with a reaction product outlet 35 and a methanol inlet 36 ; the inside is provided with packing 31 , and the top inside is provided with a demister 32 . The bottom of the reaction tower is provided with a separation liquid storage tank of the separation system, which includes a slanted baffle 38 located below the distributor 37, the reaction product outlet 35 is arranged on the side wall, and the by-product outlet 39 is arranged on the bottom surface.

[0029] The structure of the second reaction tower 4 is the same as that of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com