Manufacturing method for GaN (gallium nitride) based LED (light emitting diode) chip

A technology of LED chip and manufacturing method, applied in semiconductor/solid-state device manufacturing, semiconductor device, electrical components and other directions, can solve problems such as low contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

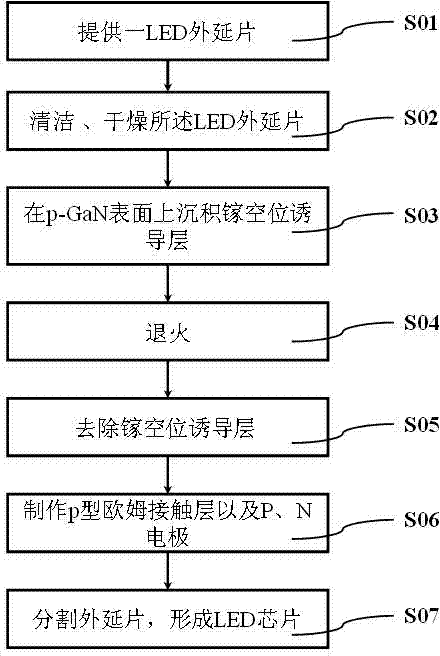

[0036] The specific implementation steps of a method for manufacturing a GaN-based LED chip are as follows:

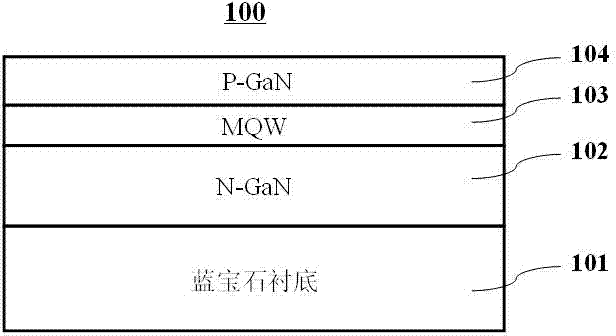

[0037] Such as figure 2 As shown, a GaN epitaxial wafer 100 (hereinafter referred to as a sample) to be fabricated is provided, including a growth substrate 101, an n-GaN layer 102, a light emitting layer 103, and a p-GaN layer 104, and the sample is cleaned with HCl, BOE, and aqua regia. and dry it.

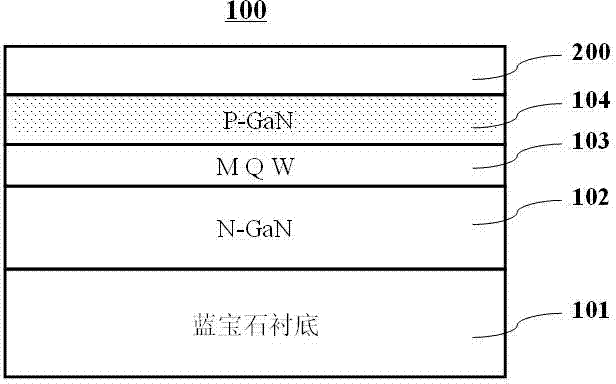

[0038] Such as image 3 As shown, a Ni / Au metal thin film is deposited on the surface of the p-GaN sample as the gallium vacancy inducing layer 200 by ion sputtering or vacuum electron beam evaporation coating equipment, the thickness of Ni is 3nm, and the thickness of Au is 10nm.

[0039] Such as Figure 4 As shown, the sample was annealed in a high-temperature furnace tube, the atmosphere was nitrogen, and the temperature was 500°C.

[0040] Such as Figure 5 As shown, the samples were successively placed in KI and dilute nitric acid solution to remove Ni / Au on t...

Embodiment 2

[0045] The difference between this embodiment and the first embodiment is that this embodiment is used to form a vertical LED chip, and the gallium holes on the surface of the activated p-GaN are processed in the same way as the first embodiment, the difference lies in the subsequent chip process, After removing the Ni / Au gallium vacancy inducing layer 200 on the sample surface, the specific steps include:

[0046] First, a Ni / Ag / Pt highly reflective p-type ohmic contact layer is fabricated on the p-GaN surface;

[0047] In the next step, a Ti / Pt / Au bonding metal layer is deposited on the entire sample surface to form a mirror metal bonding layer;

[0048] In the next step, a Si sheet is provided as a supporting substrate 600, a bonding metal layer Ti / Pt / Au is deposited on its surface, and the sample is bonded to the Si sheet using vacuum bonding equipment;

[0049] In the next step, the growth substrate of the sample is peeled off using laser lift-off equipment to expose the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com