Enhanced A1N/GaN high-electron mobility transistor and fabrication method thereof

A high electron mobility, transistor technology, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as high annealing temperature, lattice damage, poor thermal stability, etc., achieve precise control of device threshold, reduce pass State resistance, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

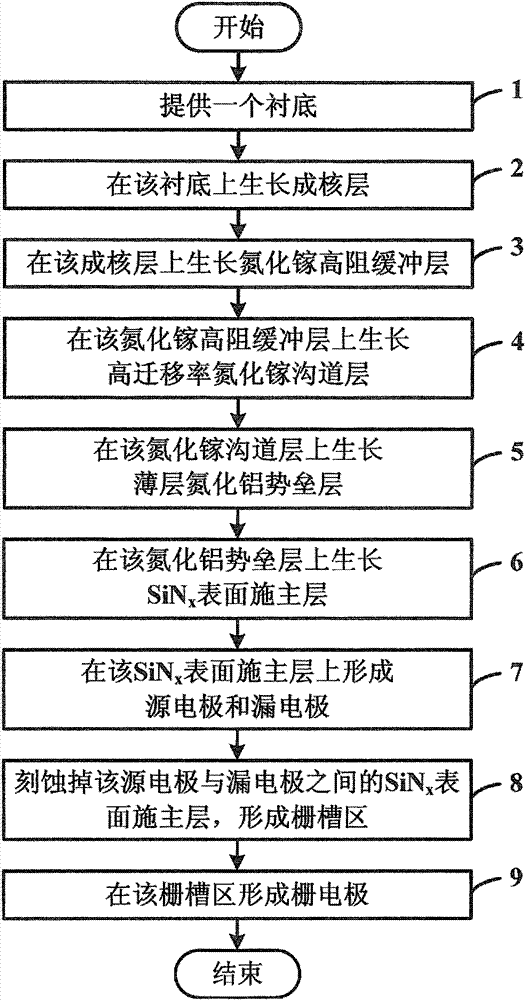

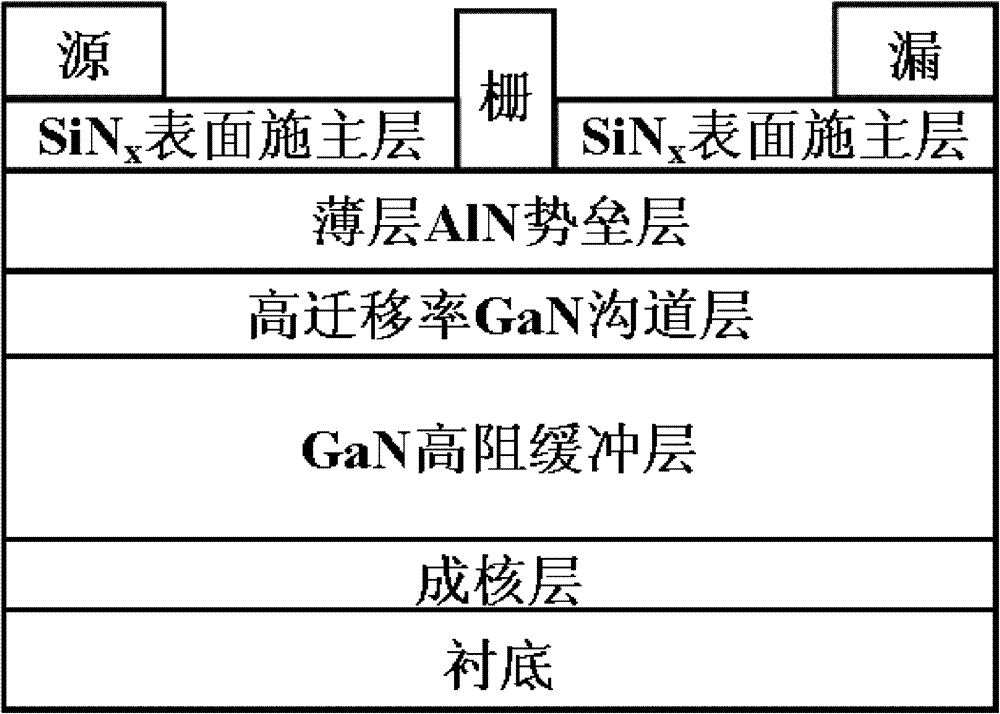

[0039] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings. Of course, they are only examples and are not intended to limit the invention.

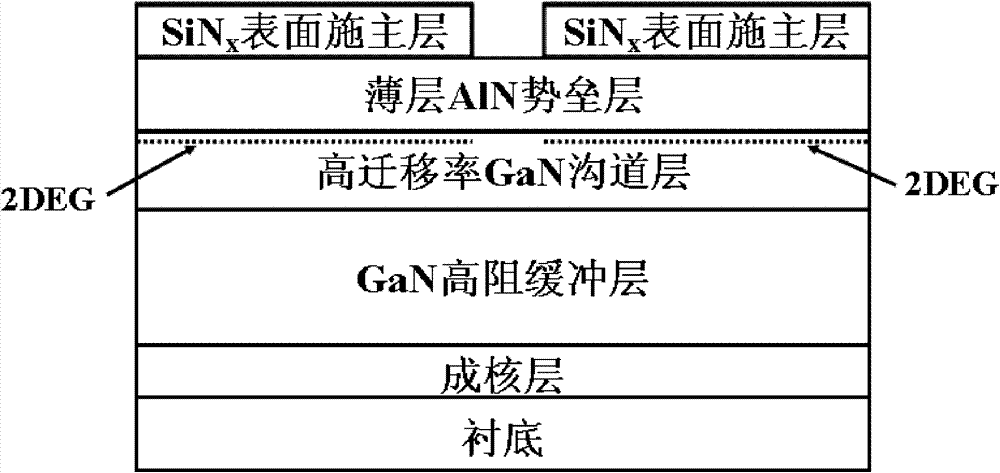

[0040] The invention utilizes epitaxial structure and material energy band control to fabricate ultra-thin barrier AlN / GaN heterojunction, so that two-dimensional electron gas (2DEG) cannot be formed at the heterojunction, and is used to realize the pinch-off region of the channel; another On the one hand, depositing SiN on the ultra-thin barrier AlN / GaN heterojunction x surface donor layer, which facilitates the SiN x A large number of positive charge donors are generated at the / AlN interface, which reduces the barrier height at the AlN surface, thereby forming a 2DEG channel at the AlN / GaN interface, and the AlN / GaN HEMT has extremely stron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com