Active oxygen disinfection system and use thereof

A surfactant, singlet oxygen technology, applied in the direction of disinfection, photoactivated composition, cleaning method and utensils, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

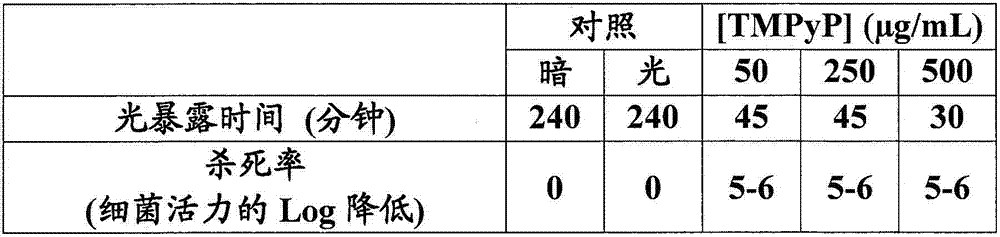

[0079] Pseudomonas aeruginosa (9027) was obtained from ATCC and reconstituted in nutrient medium according to ATCC recommendations before freezing in 10% glycerol solution. Pseudomonas aeruginosa were grown in nutrient broth for approximately 18 hours to enter the logarithmic phase of the bacteria, then spun down by centrifugation and the pellet resuspended in sterile phosphate buffered saline (PBS). The bacterial suspension was then diluted to obtain an OD of 0.9 at 540nm. The bacterial stock solution was then diluted 1:500 to obtain 5 -10 6 cfu / ml of the test solution.

[0080] Five photosensitizers were used: tetrakis(N-methyl-4-pyridyl)porphine tetramethylsylate (TMPyP) from Aldrich (Poole, Dorset, England), methylene blue (MB), toluidine blue O (TBO) and Rose Bengal (RB), and meso-tetrakis(4-sulfonatephenyl)porphine dihydrochloride (TSPP) were obtained from Frontier Scientific (Logan, Utah, U.S.A.). Solutions of one of the five photosensitizers were prepared at twice ...

Embodiment 2

[0095] Prepare the bacterial stock solution (Pseudomonas aeruginosa) according to the method described in Example 1, and then dilute it 1:500 to obtain a solution containing about 10 5 -10 6 cfu / ml of the test solution. Sensitizer solutions (TMPyP, MB and TBO) were prepared according to the method described in Example 1. Test solutions and control solutions were prepared according to the method described in Example 1. All solutions were then incubated for approximately 5 min at 37 °C in the dark in an orbital incubator before exposure to relevant light conditions.

[0096] Two light sources were used to evaluate the antibacterial activity of the series of photosensitizers. One is a broadband light source that emits light across the visible spectrum. This light source generates heat, so a fan is used to control the solution temperature when performing kill rate experiments. Another light source used was a red LED emitting light of a single wavelength at 630 nm. The light ...

Embodiment 3

[0109] This example illustrates the determination of absorption of photosensitizers by contact lenses. All photosensitizers were tested at a concentration of 10 μg / mL. Five lenses were tested for each photosensitizer. Experiments were performed by dipping the lenses in a photosensitizer solution and allowing them to sit overnight. Use medical tissue (medical tissue) to remove any excess liquid on the surface of the lens and record any visible color changes of the lens. The lenses were also evaluated using UV spectrometry to quantify any absorption, with blank lenses used to provide a spectral baseline. The results are shown in Table 3.

[0110] table 3

[0111]

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com