Edible fungi growth incubator

A technology for incubators and edible fungi, applied in applications, greenhouse cultivation, horticulture, etc., can solve problems such as economic loss, backward edible fungus fresh-keeping technology, increased transportation costs, etc., achieve broad market development prospects, overcome fresh-keeping sales problems, and save The effect of time and space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

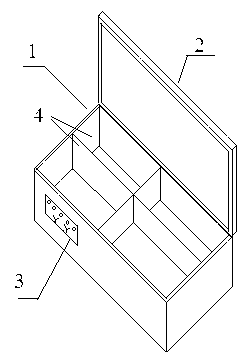

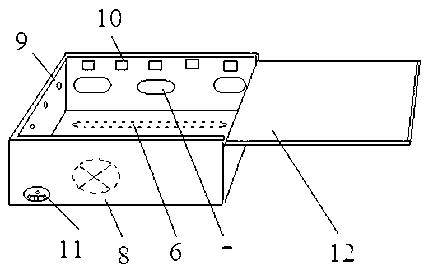

[0021] The interior of the horizontal edible fungus growth incubator is divided into four equal spaces by a partition, and a box-type incubator unit is placed in each space, and four standard edible fungus culture materials are purchased from the market. For tail mushrooms, yellow elm mushrooms and pear mushrooms, each piece of edible mushroom cultivation material is removed from the outer packaging, placed in the box-type culture unit, connected to the data plug-in line between the box-type culture unit and the box, and the box is closed Close the door, turn on the main power switch, and adjust the control conditions of each cassette incubator unit, including temperature 18-21°C, humidity 95-100%, ventilation (3-4 times a day, 2 hours each time) and light (accumulated daily 200~300Lux), that is, the growth rate of edible fungi in the cultivation material block can be controlled, and fresh edible fungus products can be picked continuously after one week.

example 2

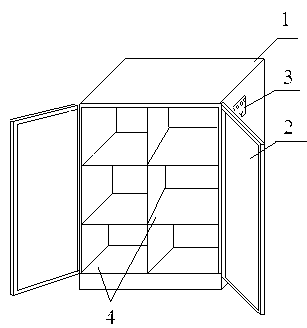

[0023] The interior of the vertical edible fungus growth incubator is divided into six equal spaces by a partition, and a box-type incubator unit is placed in each space, and six standard edible fungus culture blocks are purchased from the market, and the varieties are black fungus, slippery Mushroom, Coprinus comatus, Straw mushroom, Agaricus bisporus and Stropharia, remove the outer packaging of each piece of edible fungus cultivation material, place it in the box-type culture unit, connect the box-type culture unit and the box Plug in the data line, close the airtight door of the box, turn on the main power switch, and adjust the control conditions of each cassette incubator unit, including temperature 16-22°C, humidity 98-100%, ventilation (3-5 times a day, 1 ~2 hours) and light (accumulative 250~330Lux per day), the growth rate of edible fungi in the cultivation material can be controlled, and fresh edible fungus products can be picked continuously after one week.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com