Exchange modification method for reducing content of sodium oxide in Y-type molecular sieve

A molecular sieve and sodium oxide technology, which is applied in the directions of favhedral crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve problems such as difficulty in implementation, difficulty, ammonia nitrogen pollution, etc., and reduce water consumption, waste water discharge, crystallinity, etc. The effect of improving and eliminating the problem of ammonia nitrogen pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

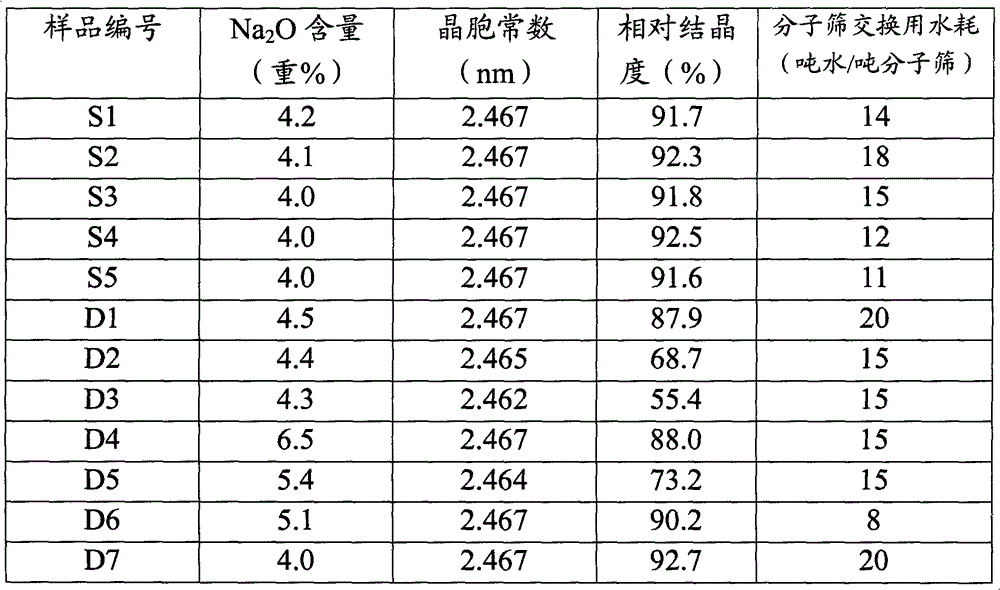

Embodiment 1

[0020] Weigh 2.7 grams of acetic acid, add an appropriate amount of cold water and stir to dissolve it, then add 8.1 grams of hydrochloric acid with a concentration of 36% by weight, and then continue to add cold water to dilute the solution to 1000ml to form a low-concentration mixed acid solution. Control the solution temperature: 3.5±0.5°C , add Y-type molecular sieve former powder dry base 71.4 grams (H 2 O: The weight ratio of molecular sieve raw powder dry base=14:1), then stirred and reacted at 3.5±0.5°C for 2 hours, then filtered the slurry, and the filter cake was rinsed with deionized water 5 times the weight of Y-type molecular sieve raw powder and drying to obtain a molecular sieve sample exchanged once with a low-temperature and low-concentration mixed acid solution, which is denoted as S1. Its properties and exchange water consumption are shown in Table 1.

Embodiment 2

[0022] Weigh 5.67 grams of oxalic acid, add an appropriate amount of cold water and stir to dissolve it, then add 15.75 grams of nitric acid with a concentration of 20% by weight, and then continue to add cold water to dilute the solution to 1000ml to form a low-concentration mixed acid solution. Control the solution temperature: 4.5±0.5°C , add Y-type molecular sieve former powder dry base 55.6 grams (H 2O: The weight ratio of molecular sieve raw powder dry base = 18:1), then stirred and reacted at 4.5±0.5°C for 2.5 hours, then filtered the slurry, and the filter cake was rinsed with deionized water 5 times the weight of Y-type molecular sieve raw powder and drying to obtain a molecular sieve sample exchanged once with a low-temperature and low-concentration mixed acid solution, which is denoted as S2. Its properties and exchange water consumption are shown in Table 1.

Embodiment 3

[0024] Weigh 12.8 grams of citric acid, add an appropriate amount of cold water and stir to dissolve it, then add 3.27 grams of phosphoric acid with a concentration of 50% by weight, then continue to add cold water to dilute the solution to a low-concentration mixed acid solution of 1000ml, control the solution temperature: 1 ± 0.5 ° C, Add Y-type molecular sieve former powder dry base 66.7 grams (H 2 O: The weight ratio of molecular sieve raw powder dry base = 15:1), then stirred and reacted at 1±0.5°C for 3 hours, then filtered the slurry, and the filter cake was rinsed with deionized water 5 times the weight of Y-type molecular sieve raw powder and drying to obtain a molecular sieve sample exchanged once with a low-temperature and low-concentration mixed acid solution, which is denoted as S3. Its properties and exchange water consumption are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com