System for using waste heat of fermentation broth and biogas slurry obtained by anaerobic fermentation biogas production and use method therefor

An anaerobic fermentation and anaerobic fermentation tank technology, which is applied in the field of anaerobic fermentation biogas fermentation liquid and biogas slurry waste heat utilization system, can solve the problems of heat loss, high heat preservation cost, economic damage, etc., to reduce mixing costs, reduce Effects of transportation cost and floor space reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

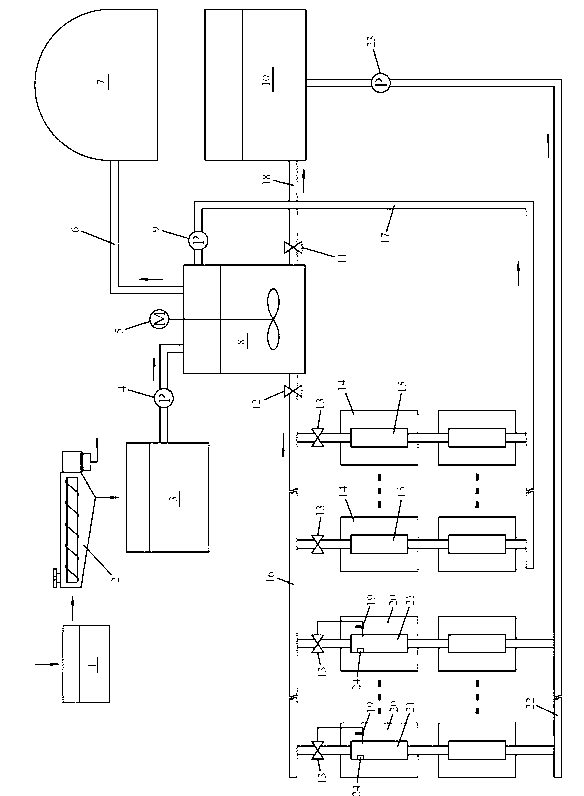

[0039] Example: see figure 1 Before the anaerobic fermentation tank 8 of the present invention, the pulverized raw materials are put into a hydrolysis tank 1 with a temperature of 50-80° C. and a pH of 9-10 for hydrolysis, and then a screw press 2 is used to squeeze the hydrolyzed raw materials to obtain fermentation raw materials liquid, remove the insoluble solids, and the fermentation raw material liquid is collected in the raw material pool 3, and the fermentation raw material liquid in the raw material pool 3 is adjusted to below the organic matter concentration VS10% and then pumped into the anaerobic fermentation tank 8 by the raw material pump 4 for fermentation , the agitator 5 is arranged in the anaerobic fermentation tank 8, and the gas collecting pipe 6 at the top of the anaerobic fermentation tank 8 is connected to the biogas storage tank 7; The fermented liquid export pipeline 16 is provided with a fermented liquid valve 12, and the fermented liquid exported pipe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com