Plate type coupled low-temperature flue gas waste heat recovery device used for air heating

A waste heat recovery device and air heating technology, used in lighting and heating equipment, indirect heat exchangers, indirect carbon dioxide emission reduction, etc. problem, to achieve the effect of compact structure, stable operation and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

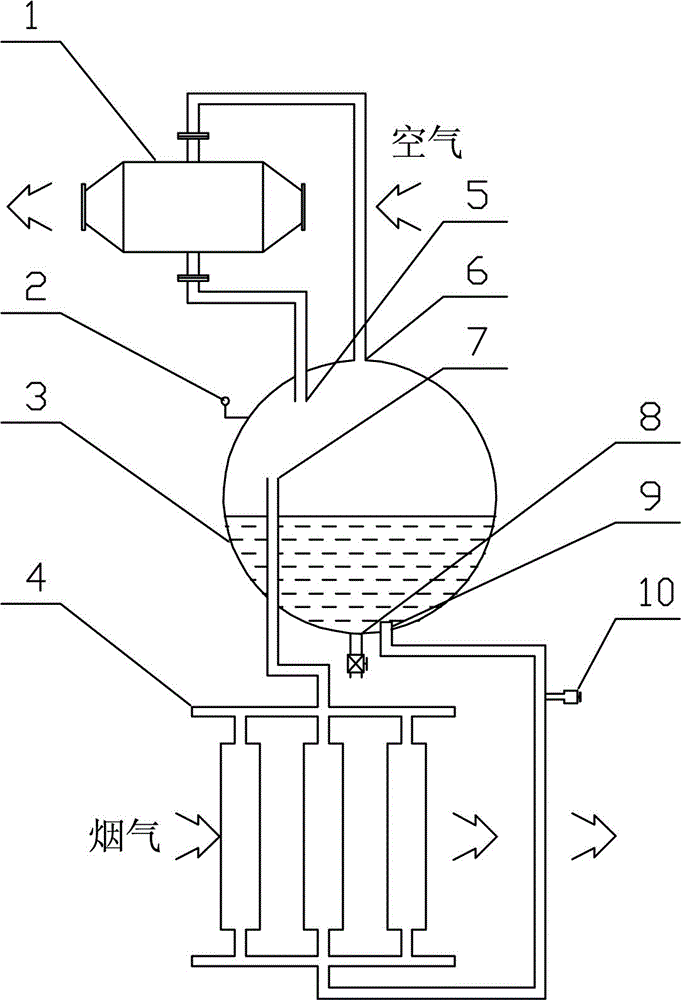

[0014] Such as figure 1 As shown, a plate-type coupled low-temperature flue gas waste heat recovery device for air heating of the present invention includes a waste heat recovery unit and an air heating unit, and the phase change working medium in the waste heat recovery unit and the air heating unit constitutes a closed cycle loop The waste heat recovery unit is composed of a finned heat pipe heat exchanger 4, the inside of the finned tube is a phase change flow channel, the outside of the finned tube is a flue flow channel, and the air heating unit is composed of a plate steam - The air heat exchanger 1 is composed of a steam-water separation drum 3 on the connecting pipeline between the waste heat recovery unit and the air heating unit, a pressure gauge 2 is provided on the steam-water separation drum, and the cold water of the finned heat pipe heat exchanger The inlet pipe 9, the steam outlet pipe 7, the steam inlet pipe 6 and the cold water outlet pipe 5 of the plate stea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com