Cosmetics, mask and cleansing cream

A technology for cosmetics and facial cleansing cream, which is applied in the directions of cosmetics, cosmetics, cosmetic preparations, etc., can solve problems such as the influence of heat-sensitive substances and effective substances on the biological activity, the inability to maintain pumpkin nutrients, and the loss of pumpkin nutrients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

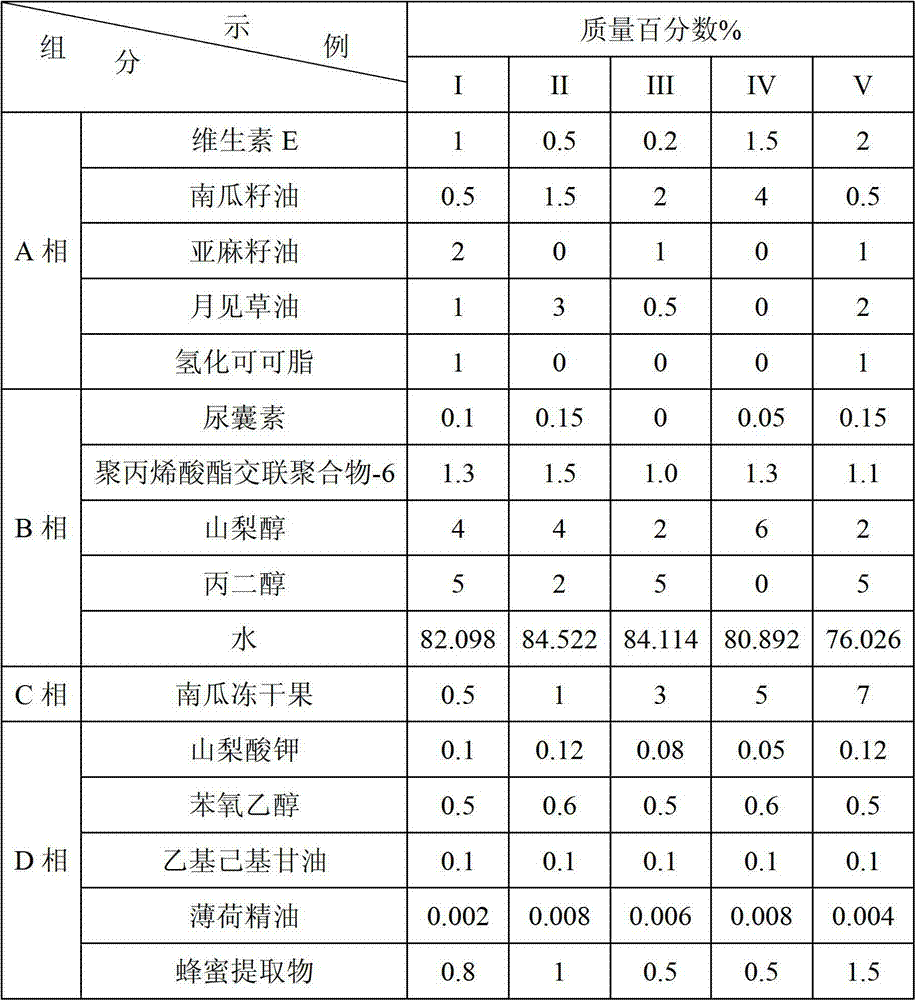

[0041] Example 1 Honey Mint Pumpkin Mask

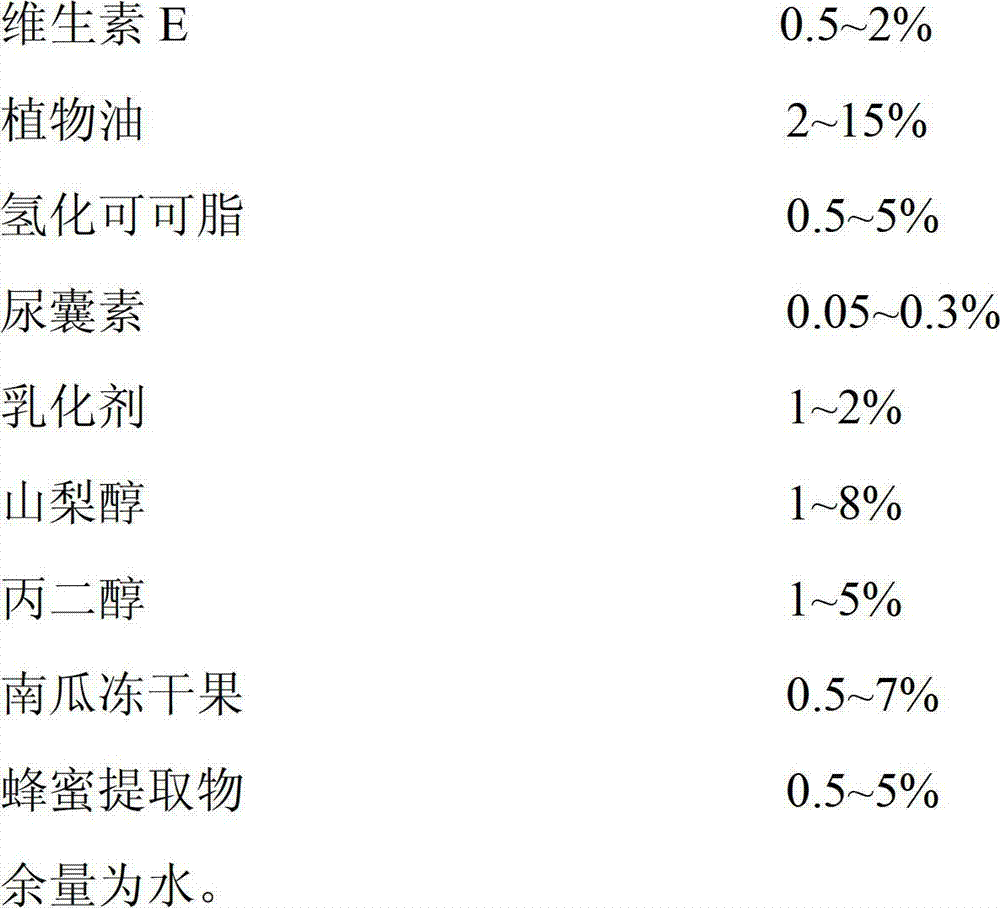

[0042] A kind of honey mint pumpkin facial mask, its each component distribution ratio and content are as shown in the following table:

[0043]

[0044] continued

[0045]

[0046]

[0047] Above-mentioned facial film can be prepared by conventional facial film production process, and in a preferred embodiment of the present invention, it comprises the following steps:

[0048] 1) Put the above-mentioned phase A components into the oil phase pot, heat to 60°C under stirring, and keep warm after the components are dissolved.

[0049] 2) Put the components of phase B into the emulsification pot, heat to 80°C, keep warm for 20 minutes, and then cool to 60°C.

[0050] 3) Pump the solution in the oil phase pot in step 1) into the emulsification pot in step 2), homogenize (3000rpm homogenization speed) for 3 minutes, then keep stirring at 60°C (30rpm stirring speed) for 20 minutes.

[0051] 4) Cool the mixture in step 3) to 45°...

Embodiment 2

[0056] Embodiment 2 Pumpkin amino acid cleansing cream

[0057] A pumpkin amino acid cleansing cream, the distribution ratio and content of each component are as shown in the table below:

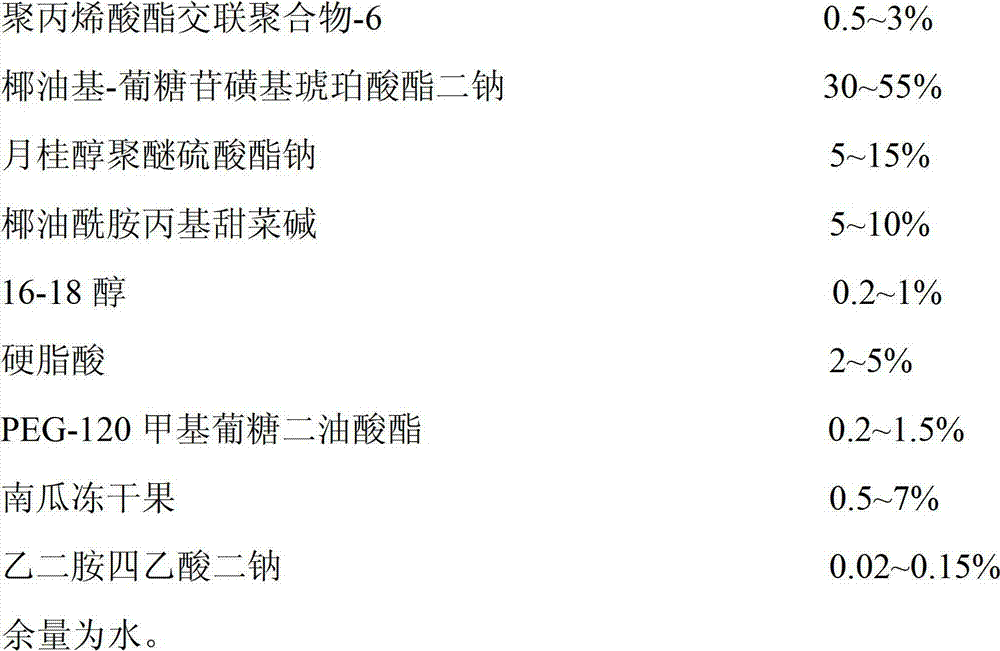

[0058]

[0059] continued

[0060]

[0061]

[0062] The mass ratio of C16:C18 in the 16-18 alcohol in each of the above examples is 4:6.

[0063] Above-mentioned cleansing cream can be prepared by conventional cleansing cream production process, in a preferred embodiment of the present invention, it comprises the following steps:

[0064] 1) Put the components of phase A into the oil phase pot, stir and heat to 75°C, after all the substances are melted, keep warm for use.

[0065] 2) Disperse the freeze-dried pumpkin fruit evenly with a small amount of deionized water in advance.

[0066] 3) Cool the oil phase pot in step 1) to 40°C, then add the pumpkin freeze-dried fruit and ethylenediaminetetraacetic acid disodium (EDTA-2Na) that have been uniformly dispersed with deionized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com