System for treating and recovering dimethyl oxalate

A technology of dimethyl oxalate and recovery system is applied in the field of systems for processing dimethyl oxalate crystallization and recovery, and can solve problems such as affecting the normal operation of the system, reducing the efficiency of producing ethylene glycol, and being inconvenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

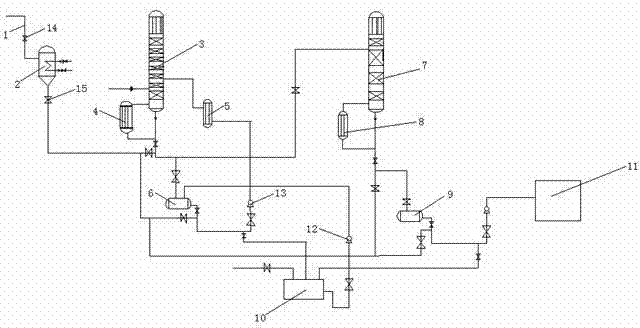

[0014] Below in conjunction with accompanying drawing, describe in further detail:

[0015] Such as figure 1 As shown, the system includes the carbonylation reaction system commonly used in the prior art, and the DMO described in the present invention is the abbreviation of dimethyl oxalate, and the input end of the carbonylation reaction system is connected with the nitrogen main pipe 1 and the hydrogenation reaction system respectively. 11 connected, the carbonylation reaction system includes DMO scrubber 3, scrubber reboiler 4, circulating cooler 5, DMO crude product tank 6, DMO recovery tower 7, recovery tower reboiler 8 and DMO product tank 9, The devices are connected with each other by pipelines, and the pipelines are made of aluminum profiles. There are 1 to 3 valves on the connecting pipelines of each device. The system also includes a gas heater and a DMO recovery tank 10, because other inert gases are used in industrial production. It is not easy to extract, so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com