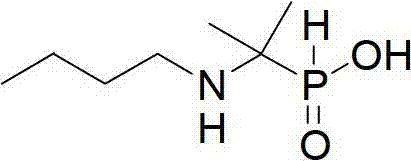

Method for preparing novel metabolic accelerator butafosfan

A technology of butafosin and hypophosphorous acid, which is applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc. , Easy industrial production, high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

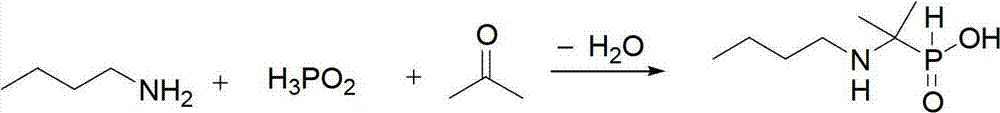

Method used

Image

Examples

Embodiment 1

[0025] Put 108kg of n-butylamine into the reaction kettle, add 300l of acetone, and dissolve 144kg of 98% hypophosphite in 50l of acetone, then add the acetone solution of hypophosphite into the solution of n-butylamine, stir for 3 hours, the system will The amine salt of hypophosphorous acid is precipitated. After the system was heated to reflux in a water bath for 4 hours, the reaction was terminated. Put the system in a cooling tank and leave it overnight, the product precipitates, filters, and centrifuges to obtain a crude product, then recrystallizes with a mixed system of 4 times the amount of methanol and acetone, keeps it warm for 1 hour, cools in a crystallization kettle, centrifuges, and dries to obtain 225kg of the product .

Embodiment 2

[0027] Put 108kg of n-butylamine into the reaction kettle, add 300l of acetone, and dissolve 155kg of 98% hypophosphite in 50l of acetone, then add the acetone solution of hypophosphite into the solution of n-butylamine, stir for 3 hours, the system will The amine salt of hypophosphorous acid is precipitated. After the system was heated to reflux in a water bath for 4 hours, the reaction was terminated. Put the system in a cooling tank and leave it overnight, the product precipitates, filters, and centrifuges to obtain a crude product, then recrystallizes with a mixed system of 4 times the amount of methanol and acetone, heats it for 1 hour, cools in a crystallization kettle, centrifuges, and dries to obtain 230kg of the product .

Embodiment 3

[0029] Put 108kg of n-butylamine into the reaction kettle, add 300l of acetone, and dissolve 165kg of 98% hypophosphite in 50l of acetone, then add the acetone solution of hypophosphite into the solution of n-butylamine, stir for 3 hours, the system will The amine salt of hypophosphorous acid is precipitated. After the system was heated to reflux in a water bath for 4 hours, the reaction was terminated. Put the system in a cooling tank and leave it overnight, the product precipitates, filters, and centrifuges to obtain a crude product, then recrystallizes with a mixed system of 4 times the amount of methanol and acetone, keeps it warm for 1 hour, cools in a crystallization kettle, centrifuges, and dries to obtain 235kg of the product .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com