Microcapsule dispersion stabilizer, microcapsule emulsion and paper for daily use

A dispersion stabilizer and household paper technology, which is applied in papermaking, paper coating, textiles and papermaking, etc., can solve problems affecting the performance of microcapsule materials, agglomeration of microcapsule suspensions, loss of functional materials, etc., and achieve reduction Tendency to aggregate, increase storage time, and reduce the effect of volatilization speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0028] The first embodiment of the present invention provides a microcapsule dispersion stabilizer, the microcapsule dispersion stabilizer is mainly formed by mixing a dispersant, a lubricant and a moisturizing agent, wherein, in the microcapsule dispersion stabilizer, the dispersant, The mass ratio of the lubricant and the moisturizing agent is 0.02-1.6:1-60:20. That is, 20 parts by mass of the humectant corresponds to 0.02 to 1.6 parts by mass of the dispersant, and 1 to 60 parts by mass of the lubricant.

[0029] Wherein, the lubricant can be selected from one of mineral liquid lubricating oil, synthetic liquid lubricating oil, non-petroleum base lubricating oil, and animal and vegetable oil, and the dispersant can be selected from cellulose derivatives, lignin sulfonate, polymer Acrylic acid derivatives, polycarboxylate polyesters of low or high molecular weight unsaturated acids, polycarboxylates, salts of long-chain polyamine amides, and alkanolammonium salts of block co...

no. 2 example

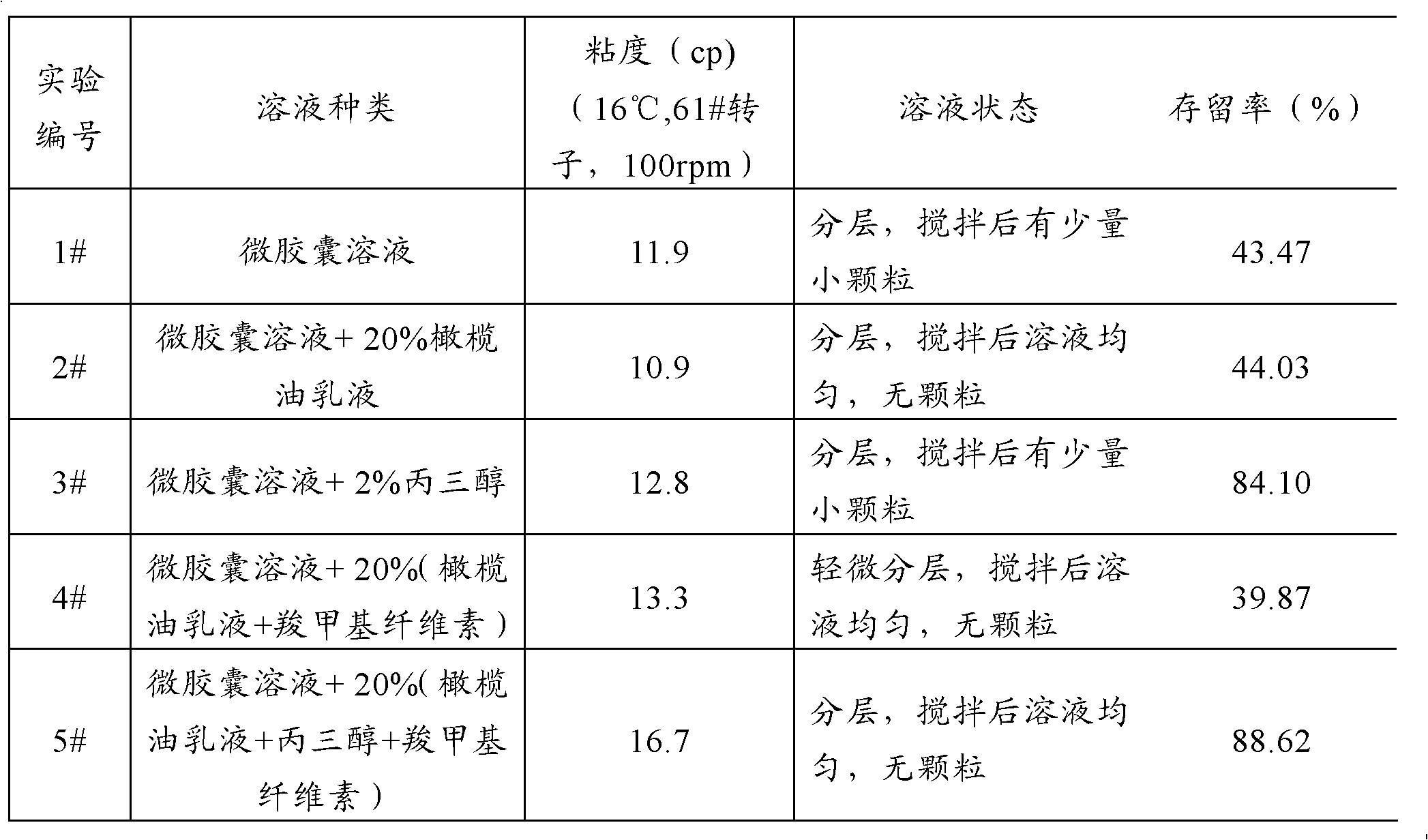

[0044] The second embodiment of the present invention provides a microcapsule emulsion, which includes microcapsule particles, and the microcapsule dispersion stabilizer provided by the first embodiment of the present invention is further mixed in the microcapsule emulsion. The microcapsule dispersion stabilizer is dispersed among the microcapsule particles to make the microcapsule particles uniformly and stably distributed in the microcapsule emulsion.

[0045] In this embodiment, the microcapsule particles can be prepared by microcapsule forming methods such as composite coacervation method, single coacervation method, phase separation method, drying bath method, interfacial polymerization method or in-situ polymerization method. After the microcapsule particles are formed by the above method, the microcapsule dispersion stabilizer of the first embodiment is added according to a certain ratio for stirring and mixing, so that the microcapsule dispersion stabilizer is dispersed...

no. 3 example

[0064] The third embodiment of the present invention provides a household paper, which includes a paper substrate, microcapsule particles and the microcapsule dispersion stabilizer of the first embodiment, the microcapsule particles are attached to the surface of the paper substrate and / or doped with In the paper matrix, the microcapsule dispersion stabilizer is dispersed among the microcapsule particles to prevent mutual aggregation between the microcapsule particles, and the microcapsule dispersion stabilizer includes a dispersant, a lubricant and a moisturizing agent.

[0065] The core material of the microcapsule particles is an oily material, preferably essence.

[0066] The wall material of the microcapsule particles is at least one selected from gelatin, gum arabic, chitin, polyurethane, polystyrene and polyacrylate.

[0067] In the microcapsule dispersion stabilizer, the lubricant is selected from mineral liquid lubricating oil, synthetic liquid lubricating oil, non-pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com