Method for making five-grain soymilk

A technology of five-grain soybean milk and its production method, applied in dairy products, milk substitutes, applications, etc., can solve the problems affecting the appearance and appetite of soybean milk, easy to appear stratification or precipitation, etc., and achieve the effect of unique flavor, delicate taste and increasing appetite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

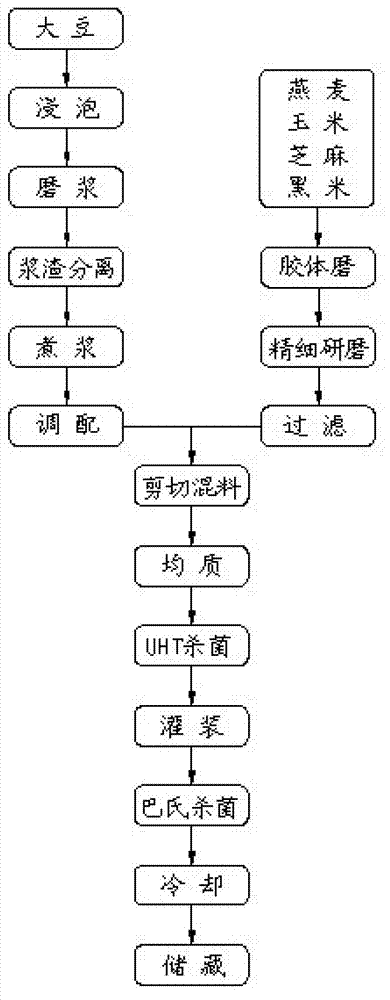

[0032] Embodiment 1: a kind of preparation method of five-grain soybean milk

[0033] See attached figure 1 Shown, a kind of preparation method of five-grain soybean milk, the raw material formula of described five-grain soybean milk is made up of the following material of mass percentage content:

[0034] Water 82-86%;

[0035] soybean 10-12%;

[0036] Sucrose 2-3%;

[0037] Oats 0.5-1%;

[0038] Black rice 0.5-1%;

[0039] Black sesame 0.5-1%;

[0040] Corn 0.5-1%;

[0041] Emulsifier 0.2-0.4%;

[0042] Fragrance 0.03-0.07%;

[0043] Sweetener 0.02-0.06%.

[0044] The preparation method includes heating soybean milk to 98-100°C, mixing oats, corn, sesame and black rice, and grinding to obtain a grain slurry; mixing soybean milk with the grain slurry, adding sucrose, spices and emulsifiers to obtain a mixed liquid; the mixed liquid is homogenized under the condition of a pressure of 35-40 MPa to obtain a homogeneous liquid, and the homogeneous liquid is sterilized a...

Embodiment 2

[0053] Embodiment 2: a kind of five-grain soybean milk and its preparation method

[0054] See attached figure 1 Shown: a method for making five-grain soybean milk, the raw material formula of the five-grain soybean milk is composed of the following materials in mass percentage:

[0055] Water 85 kg;

[0056] soybeans 10 kg;

[0057] Sucrose 2 kg;

[0058] Oats 0.8 kg;

[0059] 0.8 kg of black rice;

[0060] 0.8 kg black sesame;

[0061]0.8 kg of corn;

[0062] Emulsifier 0.3 kg;

[0063] Vanillin 0.03 kg;

[0064] Flavor 0.02 kg;

[0065] Ethyl maltol 0.02 kg;

[0066] Acesulfame K 0.02 kg.

[0067] Described preparation method comprises the following steps:

[0068] 1. Raw material acceptance: inspectors monitor the appearance, protein, moisture, and abnormal beans according to the raw material standards of soybeans and grains, and receive and put into storage if they meet the requirements.

[0069] 2. Cleaning and soaking: Put the quantitative soybeans in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com