Concentration system for rapidly concentrating slurry

A concentration system and fast technology, applied to loose filter material filters, filtration separation, separation methods, etc., can solve the problems of long concentration cycle, high concentration requirements, and large concentration cycle, so as to avoid clogging failure and improve The effect of concentration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

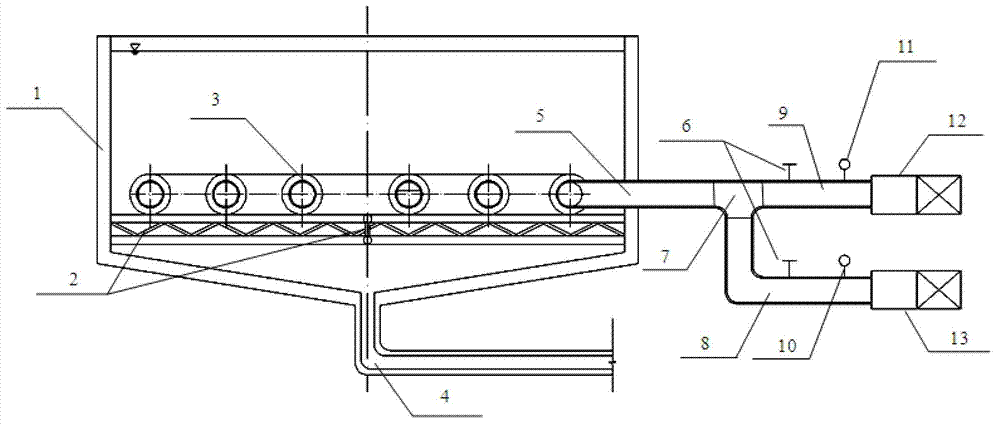

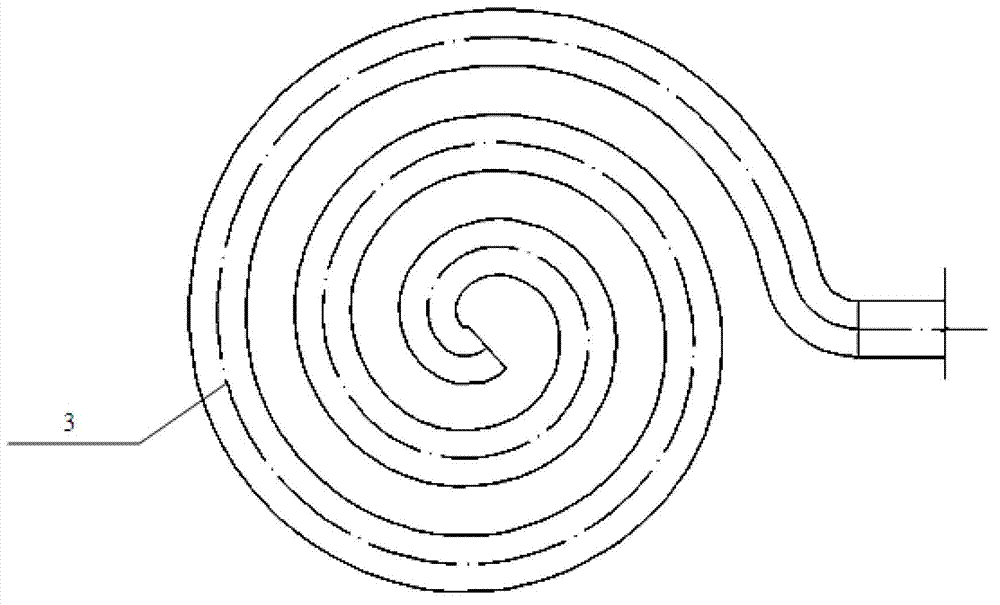

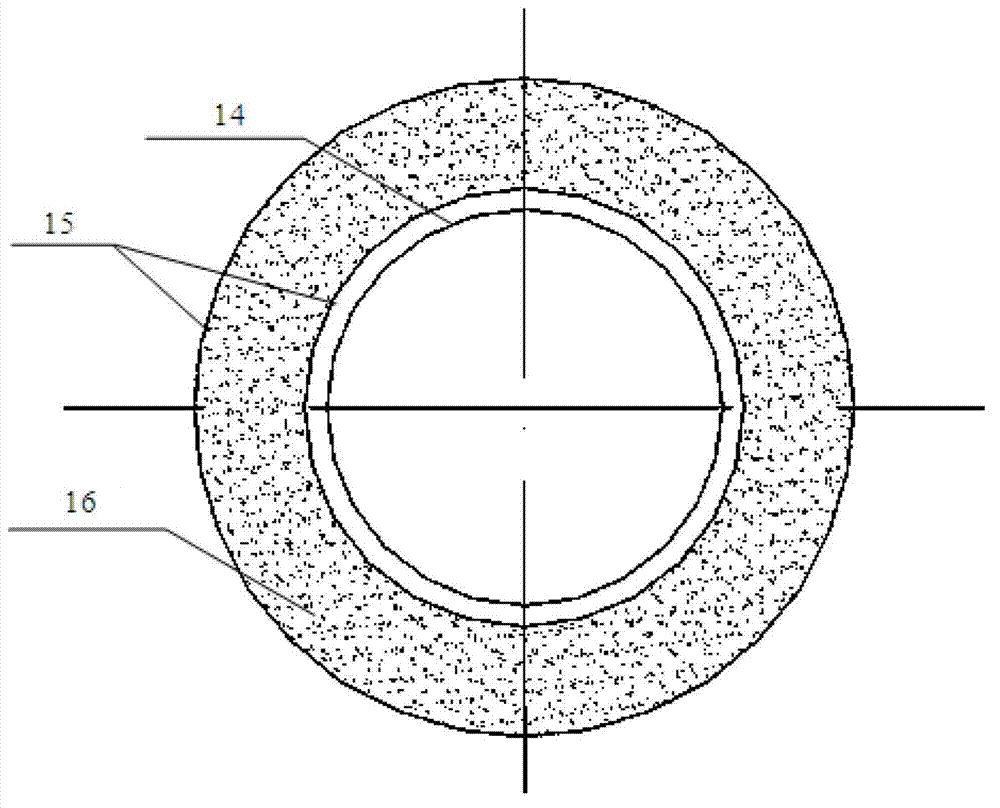

[0023] figure 1 : The present invention is used for the thickening system structure schematic diagram of quick thickening of mud, figure 2 : Schematic diagram of the structure of the vacuum filter tube, image 3 : Schematic diagram of the section of the vacuum filter tube. refer to Figure 1-3 , a concentration system for rapid concentration of mud, including a concentration tank 1 and a mud pumping pipeline 4 located below the concentration tank 1, the upper part of the concentration tank 1 is cylindrical, the lower part is funnel-shaped, the effective depth is 6m, and the diameter is 7m. The slope of the bottom of the concentration tank 1 is set to 1:5, and the vacuum suction filter tube 3 is fixed at a distance of 1.5m from the bottom of the tank; a support 2 is set on the side wall of the concentration tank, and the support 2 is composed of a cross-shaped steel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com