Water washing process for producing titanium dioxide by using sulfuric acid method which uses ascorbic acid to remove high-valence iron

A technology of ascorbic acid and titanium dioxide, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of titanium dioxide whiteness and gloss quality decline, large sewage discharge, high iron impurity content, etc., and achieve iron impurity washing and removal High efficiency, reduced water consumption, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

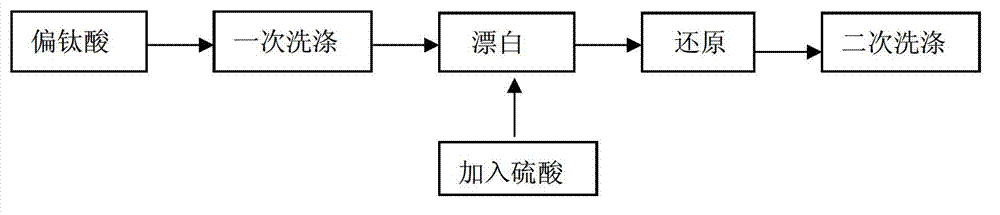

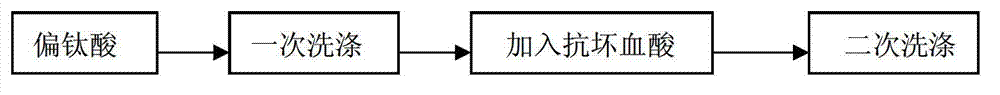

Problems solved by technology

Method used

Image

Examples

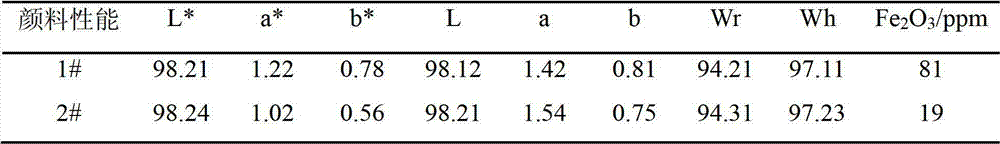

Embodiment 1

[0032] Put 200g of metatitanic acid sample in a beaker, put TiO 2 The concentration is controlled at 260±5g·L -1 , the temperature was kept within the range of 45±2°C, and ascorbic acid (concentration of TiO 2 concentration of 0.3%), adjust the stirring speed at 1500r min -1 , the reaction lasted for 30 minutes. After the reaction was balanced, it was washed with distilled water heated to 50°C, and then the filter cake was dried, dehydrated and desulfurized, and the color index was measured by the iron content measured by the fluorescence analyzer and the dry powder whiteness meter. The results are shown in Table 2.

Embodiment 2

[0034] Put 200g of metatitanic acid sample in a beaker, put TiO 2 The concentration is controlled at 300±5g·L -1 , the temperature was kept within the range of 45±2°C, and ascorbic acid (concentration of TiO 2 concentration of 0.4%), adjust the stirring speed at 1200r·min -1 , the reaction lasted for 50 minutes. After the reaction was balanced, it was washed with distilled water heated to 50°C, and then the filter cake was dried, dehydrated and desulfurized, and the color index was measured by the iron content measured by the fluorescence analyzer and the dry powder whiteness meter. The results are shown in Table 2.

Embodiment 3

[0036] Put 200g of metatitanic acid sample in a beaker, put TiO 2 The concentration is controlled at 340±5g·L -1 , the temperature was kept within the range of 45±2°C, and ascorbic acid (concentration of TiO 2 concentration of 0.5%), adjust the stirring speed at 1600r min -1 , the reaction lasted for 40 minutes. After the reaction was balanced, it was washed with distilled water heated to 50°C, and then the filter cake was dried, dehydrated and desulfurized, and the color index was measured by the iron content measured by the fluorescence analyzer and the dry powder whiteness meter. The results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com