Epoxy resin high-salinity wastewater treatment method

A technology for epoxy resin and high-salt wastewater, applied in natural water treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of difficult treatment, inability to use caustic soda for production, and high organic content , to achieve the effect of avoiding pollution, considerable economic benefits, and saving processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

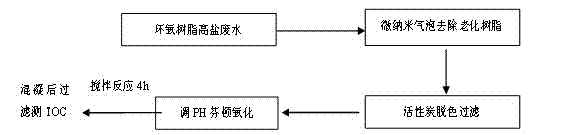

Method used

Image

Examples

Embodiment 1

[0024] 1. The quality of epoxy resin high-salt wastewater

[0025] Epoxy resin high salt wastewater quality

[0026] index pH TOC (mg / L) COD (mg / L) Salt (%) parameter 13.5 2764 5251 19

[0027] 2. Processing process and results

[0028] 2.1 Pass 1000Kg of epoxy resin high-salt wastewater through the micro-nano bubble generator, cooperate with ozone aeration, the reaction time is 4 hours, the suspended solids in the water are obviously precipitated, and the TOC in the tested water is 2414ppm after filtration.

[0029] 2.2 Take the water after micro-nano treatment, add activated carbon for adsorption, the amount of activated carbon is 0.3% (mass ratio) of the water, the reaction temperature is 70°C, and the stirring time is 40min. After the reaction, the activated carbon was removed by ordinary filtration. The effluent TOC is 2198ppm.

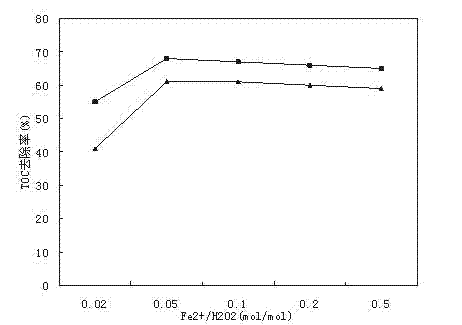

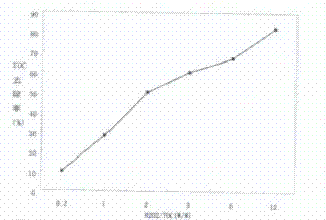

[0030] 2.3 Adjust the pH value to 3 with hydrochloric acid, add FeSO 4 ·7H 2 O 2.5Kg...

Embodiment 2

[0036] 1. The quality of epoxy resin high-salt wastewater

[0037] Epoxy resin high salt wastewater quality

[0038] index pH TOC (mg / L) COD (mg / L) Salt (%) parameter 13.5 3069 5712 19.4

[0039] 2. Processing process and results

[0040] 2.1 Pass 1000Kg of epoxy resin high-salt wastewater through the micro-nano bubble generator, cooperate with ozone aeration, the reaction time is 4 hours, the suspended solids in the water are obviously precipitated, and the TOC in the tested water is 2522ppm after filtration.

[0041] 2.2 Take the water after micro-nano treatment, add activated carbon for adsorption, the amount of activated carbon is 0.5% (mass ratio) of the water, the reaction temperature is 70°C, and the stirring time is 40min. After the reaction, the activated carbon was removed by ordinary filtration. The effluent TOC is 2042ppm.

[0042] 2.3 Adjust the pH value to 3 with hydrochloric acid, add FeSO 4 ·7H 2 O 2.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com