High power mini laser package

A laser, high-power technology, applied in the laser field, can solve the problems of the LD pump light source not being able to achieve the best effect, unable to know whether the pump light meets the requirements, unfavorable laser high-power output, etc., to achieve simple structure, convenient replacement, Easy to encapsulate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0041] It should be noted that the LD pumping light source is used to emit pumping light; the wavelength of the pumping light may have many possibilities. In the following embodiments, the wavelength of the pump light emitted by the LD pump light source is 808nm.

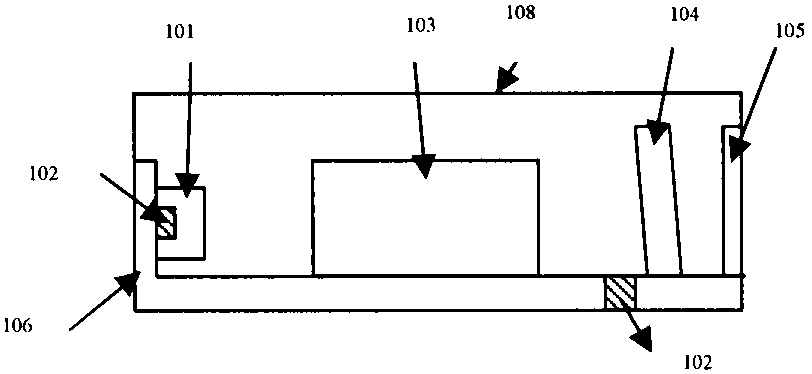

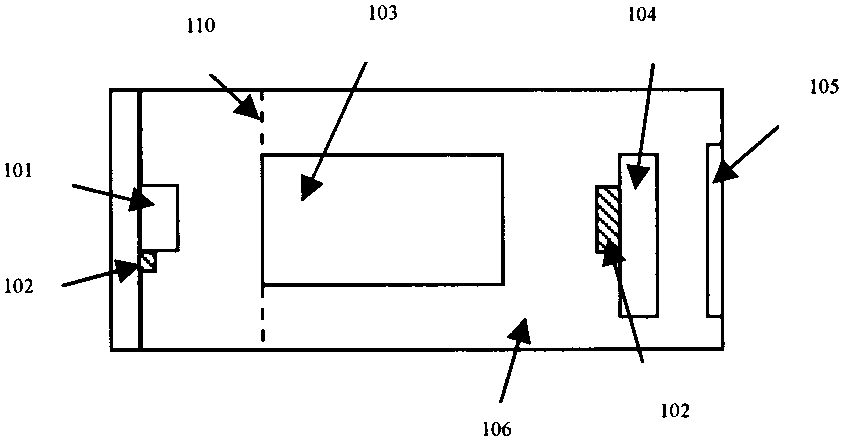

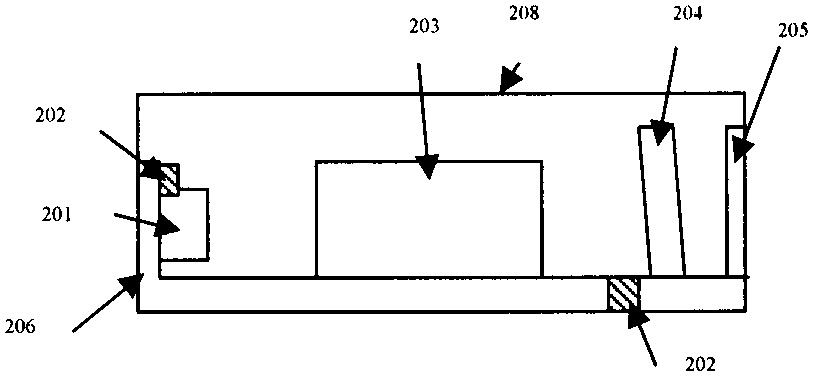

[0042] exist Figure 1a and Figure 1b It is a structural diagram of the first embodiment of the high-power compact laser of the present invention. This embodiment includes: LD pumping light source 101, vertically fixed on the side wall of metal tube shell 106, the heat generated by LD pumping light source 101 is evenly transferred to metal tube shell 106, so as to achieve better heat dissipation effect. The laser crystal and the optical frequency doubling crystal in the laser module 103 (such as the mGreen module) are coated with a special coating; The metal tube shell 106 is general...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com