Preparation method of high-bioactivity fermented soybean meal

A technology for fermented soybean meal and biological activity, applied in the field of preparation of high biological activity fermented soybean meal, can solve the problems of increased production cost, reduced labor productivity, discount of product use value, etc., and achieves reduced production cost, reduced equipment investment, and environmental protection conditions boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

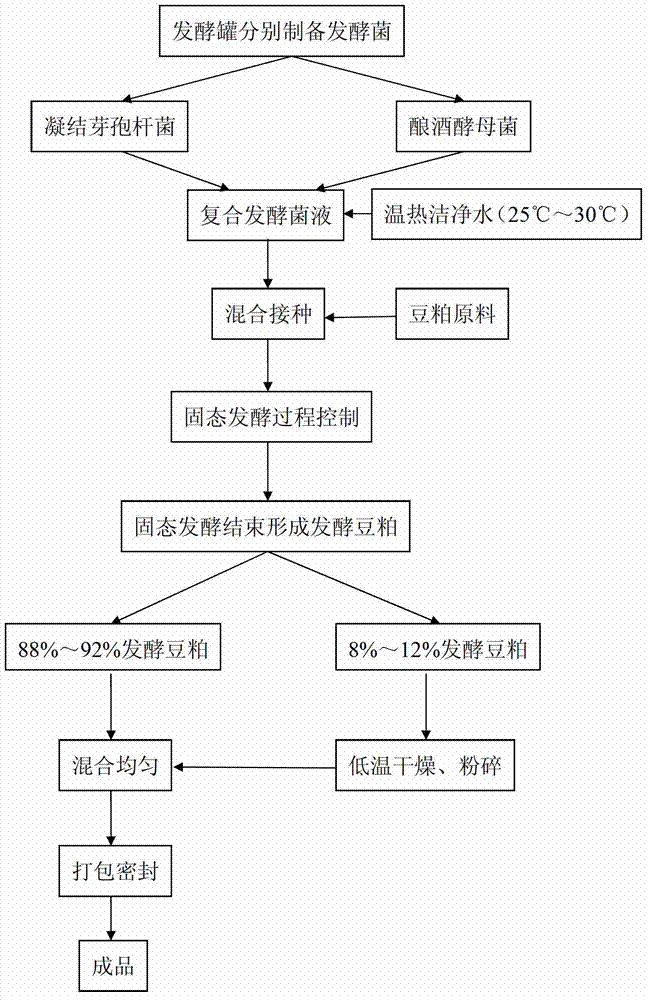

[0032] Example 1: see figure 1 As shown, the preparation method of high biological activity fermented soybean meal comprises the following steps in turn:

[0033] 1) Cultivate compound fermentation bacteria. The strains for preparing the composite fermentation bacteria are Bacillus coagulans and Saccharomyces cerevisiae, and the weight ratio of the two is 1.3:0.5.

[0034] 2) Inoculate soybean meal raw materials. First, mix the compound fermentation bacteria with warm clean water (that is, clean water with a temperature of 25-30° C.) to form a compound fermentation bacteria liquid. Afterwards, the composite fermentation bacteria liquid is evenly sprayed on the soybean meal raw material. Among them, soybean meal inoculation is carried out according to the weight ratio of soybean meal raw material: warm clean water: composite fermentation bacteria is 100:35:3. That is, take 1000kg of soybean meal raw material, 350kg of clean water, and 30kg of composite fermentation bacteria...

Embodiment 2

[0039] Example 2: see figure 1 As shown, the preparation method of high biological activity fermented soybean meal comprises the following steps in sequence:

[0040] 1) Cultivate compound fermentation bacteria. The strains for preparing the composite fermentation bacteria are Bacillus coagulans and Saccharomyces cerevisiae, and the weight ratio of the two is 1.3:2.8.

[0041] 2) Inoculate soybean meal raw materials. First mix the compound fermentation bacteria with warm clean water to form a compound fermentation bacteria liquid. Afterwards, the composite fermentation bacteria liquid is evenly sprayed on the soybean meal raw material. Among them, soybean meal inoculation is carried out according to the weight ratio of soybean meal raw material: warm clean water: composite fermentation bacteria: 100:35:5. That is, take 1000kg of soybean meal raw material, 350kg of clean water, and 50kg of composite fermentation bacteria.

[0042] 3) Fermentation of soybean meal to form fe...

Embodiment 3

[0046] Embodiment 3: see figure 1 As shown, the preparation method of high biological activity fermented soybean meal comprises the following steps in turn:

[0047] 1) Cultivate compound fermentation bacteria. The strains for preparing the composite fermentation bacteria are Bacillus coagulans and Saccharomyces cerevisiae, and the weight ratio of the two is 3.6:0.5.

[0048] 2) Inoculate soybean meal raw materials. Mix the compound fermentation bacteria with warm clean water to form a compound fermentation bacteria liquid. Afterwards, the composite fermentation bacteria liquid is evenly sprayed on the soybean meal raw material. Among them, soybean meal inoculation is carried out according to the weight ratio of soybean meal raw material: warm clean water: composite fermentation bacteria is 100:70:3. That is, take 1000kg of soybean meal raw material, 700kg of clean water, and 30kg of composite fermentation bacteria.

[0049] 3) Fermentation of soybean meal to form ferment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com