Method for removing calcium and magnesium in aloe gel juice

Aloe vera gel juice and aloe vera gel technology are applied in the field of removing calcium and magnesium from aloe vera gel juice, and can solve the problems of cloudiness of aloe vera gel juice, affecting the quality of aloe vera gel juice, etc. The effect of environmental protection and high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

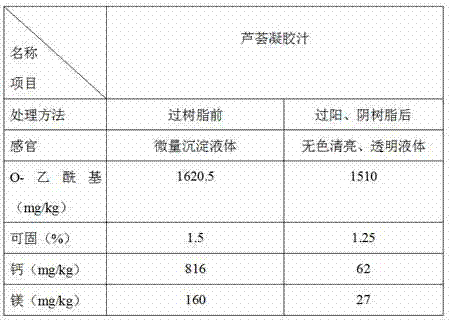

Image

Examples

Embodiment 1

[0020] A, 40 tons of aloe leaves are washed with water to remove the residual silt on the aloe leaves, and then the surface of the aloe leaves is disinfected and cleaned with a chlorine dioxide disinfectant with a concentration of 20ppm to control the growth of microorganisms, and then the aloe is treated with pure water The leaves were cleaned to remove residual disinfectants, then the side thorns and skins were removed, crushed and squeezed for juice, and sterilized for 6 seconds at a temperature of 80°C to obtain 18 tons of aloe vera juice;

[0021] B. Add 900ml of pectinase to the aloe juice obtained in step A, perform enzymolysis reaction at 50°C for 60 minutes, filter, sterilize at 120°C for 6 seconds, and cool to room temperature to obtain crude aloe juice;

[0022] C, by the volume ratio of aloe thick juice: macroporous anion resin=10:1, the aloe thick juice gained in step B is passed through macroporous anion resin, and the contact time of controlling aloe thick juice ...

Embodiment 2

[0029] A, 36 tons of aloe leaves are washed with water to remove the residual silt on the aloe leaves, and then the surface of the aloe leaves is disinfected and cleaned with a chlorine dioxide disinfectant with a concentration of 30ppm to control the growth of microorganisms, and then the aloe is treated with pure water Leaves are cleaned to remove residual disinfectant, then remove side thorns and skins, pulverize and squeeze the juice, and sterilize for 4 seconds at a temperature of 95°C to obtain 15 tons of aloe juice;

[0030] B. Add 1500ml of pectinase to the aloe juice obtained in step A, perform enzymatic hydrolysis reaction for 40 minutes at a temperature of 55°C, filter, sterilize for 4 seconds at a temperature of 125°C, and cool to room temperature to obtain crude aloe juice;

[0031] C, by the volume ratio of aloe thick juice: macroporous anion resin=15:1, the aloe thick juice gained in step B is passed through macroporous anion resin, and the contact time of contro...

Embodiment 3

[0038] A. Wash the aloe leaves with water to remove the residual silt on the aloe leaves, then disinfect and clean the surface of the aloe leaves with a chlorine dioxide disinfectant with a concentration of 40ppm to control the growth of microorganisms, and then use pure water to clean the aloe leaves Wash to remove residual disinfectant, remove side thorns and skins, crush and squeeze juice, and sterilize at 90°C for 5 seconds to obtain aloe vera juice;

[0039] B. Add 900ml of pectinase to the aloe juice obtained in step A, perform enzymolysis reaction at 52°C for 50 minutes, filter, sterilize at 122°C for 5 seconds, and cool to room temperature to obtain crude aloe juice;

[0040] C, by the volume ratio of aloe thick juice: macroporous anion resin=12:1, the aloe thick juice gained in step B is passed through macroporous anion resin, and the contact time of controlling aloe thick juice and macroporous anion resin is 23min, promptly obtains Depigmented aloe vera gel crude jui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com