Sound-proof, heat-insulated and flame-retardant lightweight aggregate magnesite coagulating composite material and composite plate thereof

A technology of composite materials and magnesite materials, applied in the field of composite boards, can solve the problems of high temperature resistance, crystal structure damage, easy deformation, etc., and achieve the effect of poor water resistance, sound insulation, heat insulation and flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

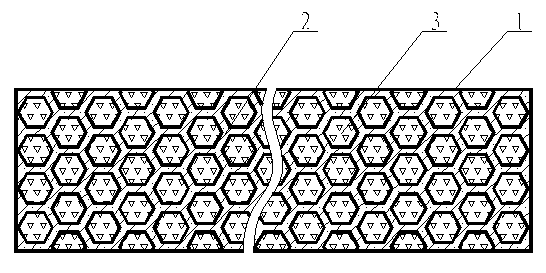

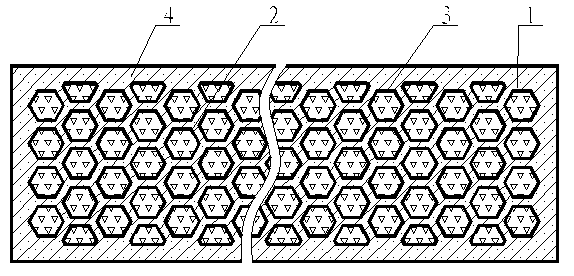

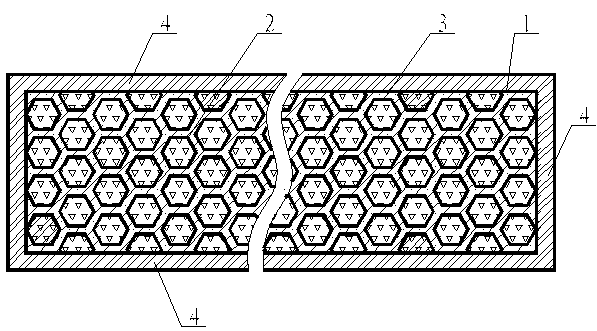

Image

Examples

Embodiment 1

[0137] Example 1: The lightweight aggregate uses polyphenylene particles, and the volume ratio of the slurry of the magnesite material to the polyphenylene particles is 1:19; the slurry of the magnesite material includes magnesium oxide and the concentration is 15 Baume The magnesium chloride aqueous solution, the weight ratio of magnesium oxide and magnesium chloride aqueous solution is 5:4.

[0138] The lightweight aggregate magnesite concrete composite material made with the proportioning of Example 1 is tested for combustion performance, and the results are shown in Table 1:

[0139] Table 1

[0140]

[0141] It can be clearly seen from Table 1 that the combustion performance of the lightweight aggregate magnesite concrete composite material in Example 1 can fully reach the A2-s1, d0, t0 grades, which is in line with the national standard.

[0142]

Embodiment 2

[0143] Example 2: what the lightweight aggregate adopts are closed-cell perlite particles, and the volume ratio of the slurry of magnesite material to the closed-cell perlite particles is 5:15; the slurry of magnesite material includes magnesium oxide and the concentration is wave The magnesium chloride aqueous solution with a beauty degree of 25, the weight ratio of magnesium oxide and magnesium chloride aqueous solution is 5:3.

[0144] See Table 2 for details with the combustion performance test results of the lightweight aggregate magnesite concrete composite material of the present invention of embodiment 2:

[0145] Table 2

[0146]

[0147] It can be clearly seen from Table 2 that the combustion performance of the lightweight aggregate magnesite concrete composite material in Example 2 can fully reach the A2-s1, d0, t0 grades, which is in line with the national standard.

[0148]

Embodiment 3

[0149] Example 3: The lightweight aggregate uses hollow vitrified microbead particles, and the volume ratio of the slurry of the magnesite material to the hollow vitrified microbead particle is 8:12; the slurry of the magnesite material includes magnesium oxide and a concentration of It is a magnesium chloride aqueous solution with a Baume degree of 35, and the weight ratio of magnesium oxide to magnesium chloride aqueous solution is: 5:2.

[0150] See Table 3 for details with the combustion performance test results of the lightweight aggregate magnesite concrete composite material of the present invention of embodiment 3:

[0151] table 3

[0152]

[0153] It can be clearly seen from Table 3 that the combustion performance of the lightweight aggregate magnesite concrete composite material in Example 3 can fully reach the A2-s1, d0, t0 grades, which is in line with the national standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com