Nanometer concentrated enzyme organic fertilizer and preparation method thereof

A technology of concentrated enzymes and organic fertilizers, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve problems such as low active ingredients, low crop yield, and slow release speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

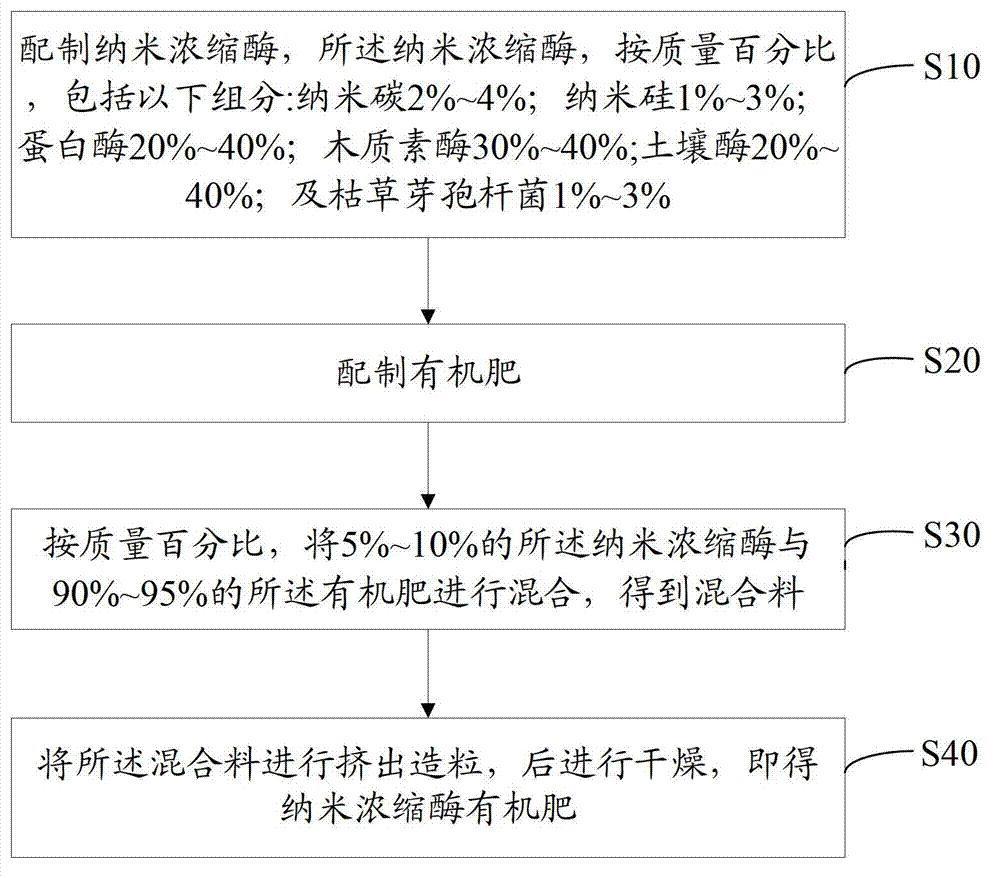

[0082] see figure 1 , the preparation method of the nano concentrated enzyme organic fertilizer of one embodiment, comprises the following steps:

[0083] Step S10, preparing nano-enzyme concentrate, said nano-enzyme, by mass percentage, includes the following components:

[0084] Nano carbon 2%~4%;

[0085] Nano silicon 1%~3%;

[0086] Protease 20%~40%;

[0087] Ligninase 30%~40%;

[0088] Soil enzymes 20%~40%; and

[0089] Bacillus subtilis 1%~3%.

[0090] Preferably, the soil enzyme is composed of the following components by mass percentage:

[0091] Sucrase 45%;

[0092] Catalase 35%; and

[0093] Phosphatase 20%.

[0094] The number of live bacteria of the bacillus subtilis is 2×10 10 CFU / g.

[0095] Step S20, preparing organic fertilizer.

[0096] Preferably, the organic fertilizer comprises the following components by mass percentage:

[0097] Plant ash 20%~30%;

[0098] Biogas fermentation residue 10%~30%;

[0099] Corn fermentation dregs 20%~30%;

[01...

Embodiment 1

[0110] Prepare nano-enzyme concentrate, said nano-enzyme concentrate, by mass percentage, includes the following components:

[0111] Nano carbon 2%;

[0112] Nano silicon 1%;

[0113] Protease 20%;

[0114] Ligninase 36%;

[0115] Soil Enzymes 40%; and

[0116] Bacillus subtilis 1%.

[0117] Prepare organic fertilizer, described organic fertilizer, by mass percentage, comprises following component:

[0118] Plant ash 20%;

[0119] Biogas fermentation residue 20%;

[0120] Corn fermented dregs 20%;

[0121] Humic Acid 30%; and

[0122] Bentonite 10%.

[0123] According to mass percentage, 1.5kg of the nano concentrated enzyme is mixed with 28.5kg of the organic fertilizer to obtain a mixture.

[0124] The mixed material is extruded and granulated, and then dried to obtain the nano concentrated enzyme organic fertilizer.

[0125] Wherein, the soil enzyme is composed of the following components by mass percentage:

[0126] Sucrase 45%;

[0127] Catalase 35%; and

...

Embodiment 2

[0132] Prepare nano-enzyme concentrate, said nano-enzyme concentrate, by mass percentage, includes the following components:

[0133] Nano carbon 2%;

[0134] Nano silicon 2%;

[0135] Protease 40%;

[0136] Ligninase 30%;

[0137] Soil Enzymes 25%; and

[0138] Bacillus subtilis 1%.

[0139] Prepare organic fertilizer, described organic fertilizer, by mass percentage, comprises following component:

[0140] Plant ash 30%;

[0141] Biogas fermentation residue 20%;

[0142] Corn fermented dregs 20%;

[0143] Humic Acid 20%; and

[0144] Bentonite 10%.

[0145] According to mass percentage, 2.1 kg of the nano concentrated enzyme is mixed with 27.9 kg of the organic fertilizer to obtain a mixture.

[0146]The mixed material is extruded and granulated, and then dried to obtain the nano concentrated enzyme organic fertilizer.

[0147] Wherein, the soil enzyme is composed of the following components by mass percentage:

[0148] Sucrase 45%;

[0149] Catalase 35%; and

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com