Sludge fuelization treatment process of urban sewage treatment plant

A technology of urban sewage and treatment process, applied in water/sludge/sewage treatment, sludge treatment, energy and wastewater treatment, etc., to achieve the effects of energy reduction, energy utilization improvement, and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

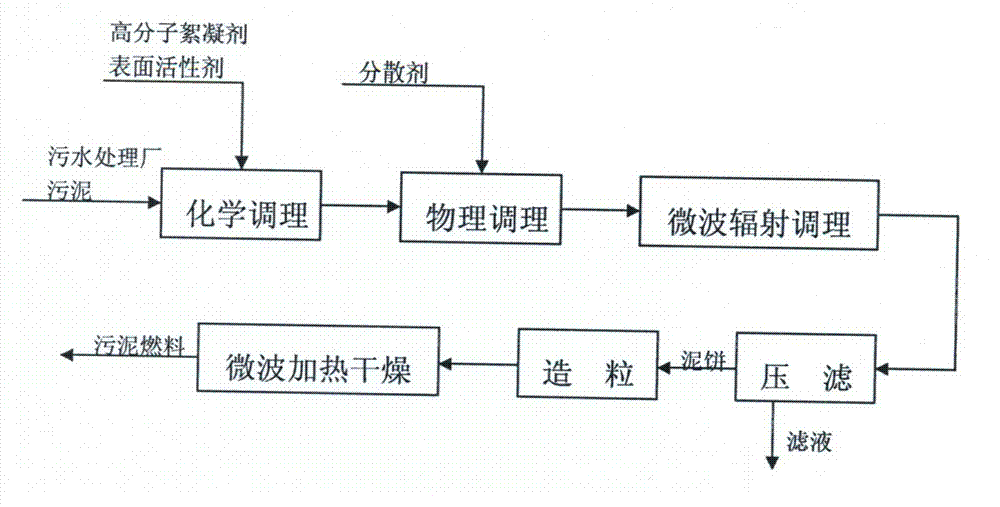

[0032] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0033] The dewatered sludge of an urban sewage treatment plant is characterized by the following characteristics: the moisture content is 82.3%, and the organic component content in the solid is 61.8%. Adopt a kind of urban sewage treatment plant sludge fuelization treatment process method of the present invention to process:

[0034] 1. Carry out chemical conditioning on the sludge. First, condition the sludge to improve the mechanical dehydration performance. Add 3.75g of polymer flocculant and 4.5g of surfactant per kilogram of sludge, and stir evenly;

[0035] 2. Physically condition the sludge, add a dispersant to the sludge in a certain proportion and stir evenly, add 125g of a dispersant per kilogram of sludge, and mix well:

[0036]3. Carry out microwave radiation conditioning on the sludge, send it into a microwave oven for microwave r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com