Automatic coupling device from optical fiber laser device to single mode optical fiber

A fiber laser and automatic coupling technology, which is applied in the coupling direction of optical waveguide, can solve the problems that the high coupling efficiency of the coupling element cannot be adjusted, the coupling efficiency cannot be further improved, and it is easily affected by the external environment, so as to achieve precise automatic adjustment function, Precise laser mode adjustment, reliable operation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

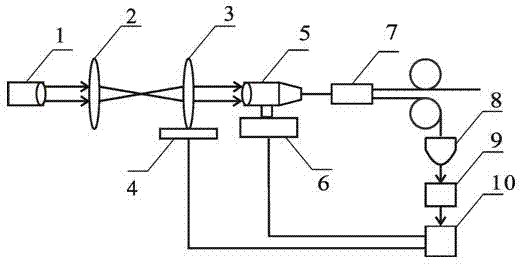

[0024] Implementation of the present invention provides an automatic coupling device from a fiber laser to a single-mode fiber, including a mode conversion optical part and an automatic adjustment part to precisely adjust the laser mode to form an automatic coupling device in which the laser mode satisfies the fiber transmission mode to the greatest extent . in:

[0025] The mode conversion optical part is to convert the laser mode to meet the optical fiber transmission mode, and the automatic adjustment part is to control the mode conversion optical device with an accuracy up to micron and can have the function of automatic real-time adjustment to make the mode conversion optical system work at the best state to form an automatic coupling device in which the laser mode satisfies the optical fiber transmission mode to the greatest extent. The specific composition of this device is as follows:

[0026] The automatic coupling device of the present invention is composed of a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com