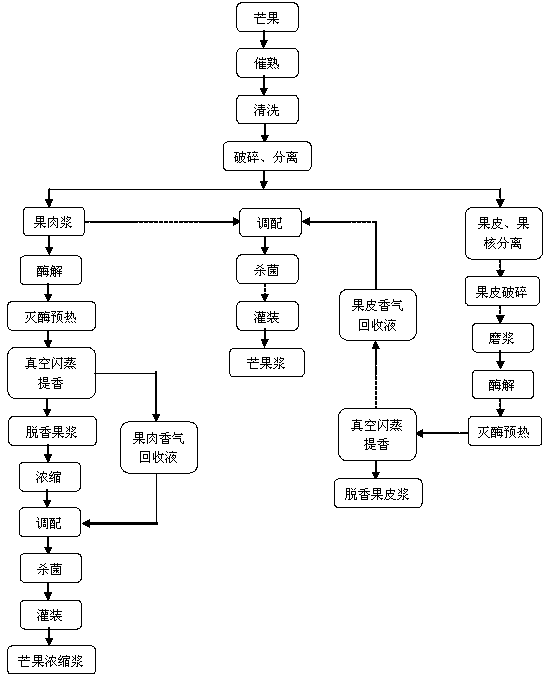

Method for enhancing aroma of mango pulp

A technology for mango pulp and mango puree, which is applied in the direction of food science and the like, can solve the problem of not finding the recovery of natural mango aroma, and achieve the effect of improving product quality and flavor, and the effect of complex aroma is natural and soft.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] After the mangoes are ripened to full ripeness, obviously rotten and diseased mangoes are removed, then cleaned to remove stains, and the pulp, peel and core are broken and separated. The collected peels are crushed with a squirrel cage crusher, and the mass ratio is peel: water = 1: 1.5~2.5, mixed with water and sent to a beater, and then ground into a slurry through a colloid mill.

[0027] Use edible grade citrate buffer to adjust the pH value of the slurry to 4.00, stir evenly, heat the skin slurry to 50°C through a plate heat exchanger, add pectinase 0.005 with enzyme activity ≥ 500,000 U / g according to the mass ratio of mango raw materials %, other enzyme preparations were not added, and the enzymatic hydrolysis treatment was started for 30 minutes; after the enzymatic hydrolysis, the enzymatic hydrolysis solution was quickly heated to 95°C through a plate heat exchanger, and the enzyme was deactivated and preheated, and then transported to vacuum flash evaporation...

Embodiment 2

[0031] Raw material acceptance and pretreatment are the same as in Example 1. The obtained slurry is heated to 45°C by a plate heat exchanger, and 0.15% of cellulase with enzyme activity ≥ 1 million U / g is added according to the mass ratio of mango skin, and the amount of other enzymes is zero, and the food grade citrate buffer is used to adjust the slurry The pH value is 5.00, stir evenly, start the enzymatic hydrolysis treatment, and the time is 40min; after the enzymolysis is completed, it is heated to 95°C by a plate heat exchanger, and the enzyme is inactivated and preheated, and it is transported to the vacuum flash aroma recovery system for separation Condensate to obtain mango peel aroma recovery liquid.

[0032] The sugar content of mango puree obtained on the same production line is 18Brix. According to the sugar content requirement of mango pulp products, the sugar content is 13Brix. According to the mass of mango pulp, 27.8% mango peel aroma recovery liquid is mixe...

Embodiment 3

[0035] Raw material acceptance and pretreatment are the same as in Example 1. The obtained slurry is heated to 55°C by a plate heat exchanger, and 0.02% of xylanase with an enzyme activity ≥ 20 million U / g and cellulose with an enzyme activity ≥ 1 million U / g are added according to the mass ratio of mango skin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com